Air Quality Monitoring using LoRaWAN

Maintaining good air quality in warehouse environments is crucial for employee health, hygiene, and operational efficiency. Amazon identified recurring air quality concerns in washrooms due to the buildup of gases like H₂S (Hydrogen Sulfide) and NH₃ (Ammonia), which can lead to unpleasant odors, discomfort, and potential health risks for workers.

To address this, Macnman Technologies deployed a smart IoT-based air quality monitoring system powered by LoRaWAN®, ensuring continuous environmental monitoring, real-time alerts, and improved hygiene maintenance.

Problem Identified: Poor Air Quality & Worker Discomfort

Large-scale warehouse washrooms experience high foot traffic and limited ventilation. Over time, this leads to:

Unnoticed Gas Accumulation

Hydrogen sulfide (H₂S) and ammonia (NH₃) were not tracked continuously, risking employee comfort and safety.

Poor Odor

Dust and odors (PM2.5/PM10) accumulated, affecting cleanliness perception and hygiene standards.

Delayed Alerts

Without real-time monitoring, issues were only detected after complaints, causing delays in maintenance.

Operational Risk

Poor air quality impacted employee satisfaction, safety, and warehouse hygiene.

Smart IoT Solution for Air Quality and Hygiene Optimization

To ensure healthy and hygienic washrooms, we deployed a LoRaWAN-based AQI and gas monitoring system in Amazon’s warehouse

- 01

Continuous AQI Monitoring

Real-time tracking of H₂S, NH₃, and CO₂ levels ensures safe air quality in warehouse washrooms.

- 02

LoRaWAN-Based Connectivity

Long-range, low-power wireless network enables reliable data transmission without Wi-Fi dependency.

- 03

Automated Alerts & Notifications

Instant alerts sent to the control room when harmful gas thresholds are crossed.

- 04

Seamless SCADA Integration

AQI data integrated directly into the warehouse’s SCADA dashboard for centralized monitoring

- 05

Low Power & Maintenance-Free

Sensors designed for years of operation with minimal servicing, ideal for remote or enclosed spaces.

- 06

Improved Workplace Hygiene & Safety

Prevents gas buildup and ensures a healthy, compliant environment for warehouse staff.

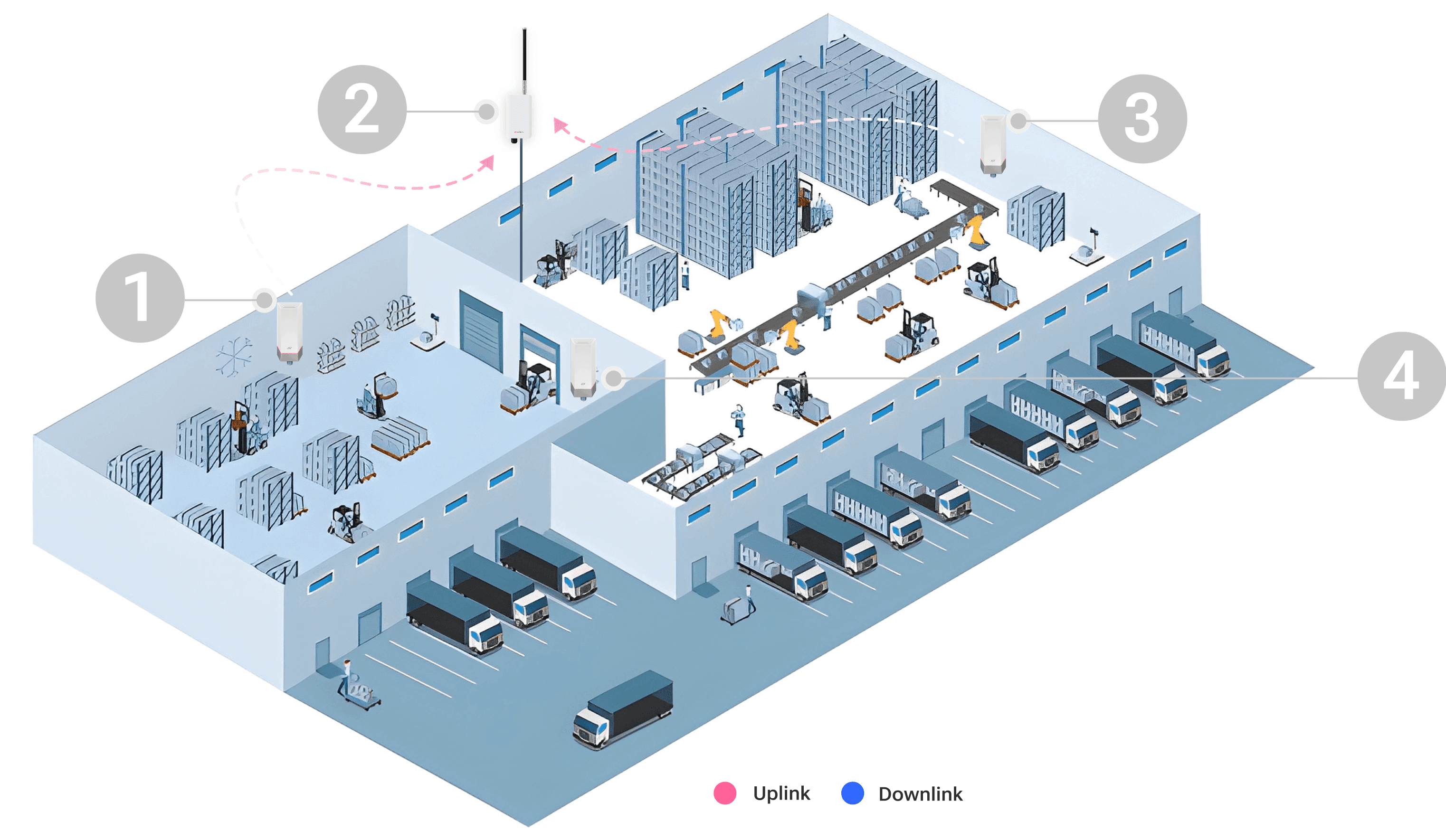

IoT Architecture for Smart Air Quality Monitoring

Deployment of IoT-Enabled Air Quality System

The deployment took place across multiple warehouse washrooms and service areas, focusing on maintaining healthy air quality and worker safety.

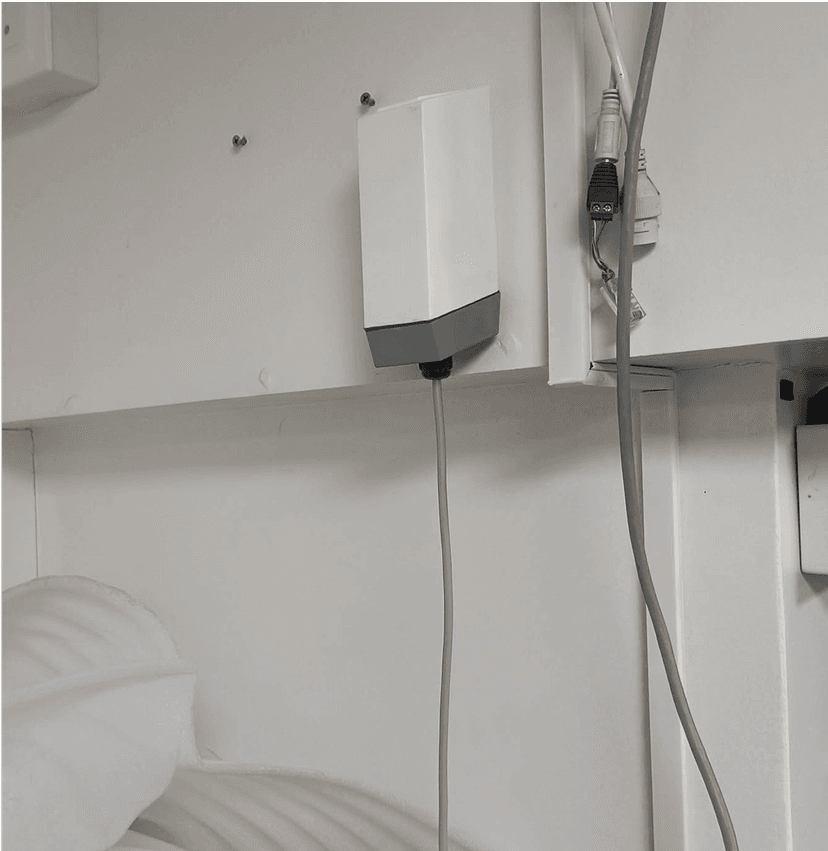

MacSync LoRaWAN AQI Node

Mounted near drainage and cleaning areas to identify ammonia buildup from cleaning agents and waste residue.

Industrial LoRaWAN Gateway

Provided long-range data transmission across the entire warehouse complex, ensuring seamless cloud connectivity and backup storage..

SCADA Dashboard

All devices communicated through Macnman’s secure LoRaWAN network, with data forwarded to the SCADA dashboard.

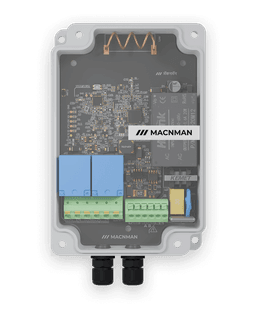

MacSet Controller with Andon Light

Installed outside washrooms and at key measuring points to provide visual alerts whenever gas concentrations exceed safe thresholds.

Challenges in Deploying Smart Air Quality Monitoring

Accurate Sensor Calibration

H₂S, NH₃, and CO₂ sensors needed precise field calibration to maintain reliable readings under varying humidity and temperature conditions.

Visual Alert Integration

Synchronizing the MacSet Andon lights with sensor thresholds required careful configuration to avoid false alerts and ensure timely staff response.

Long-Term Reliability

Ensuring continuous operation with minimal maintenance while maintaining battery life and sensor accuracy in high-traffic areas.

Data Consistency

Integrating real-time sensor data with the warehouse’s SCADA dashboard demanded robust network management and redundancy measures.

Impact: Cleaner, Safer, and Smarter Warehouses

Real-Time Air Quality Visibility

Facility managers now monitor H₂S, NH₃, and CO₂ levels instantly across all washrooms.

Automated Safety Alerts

MacSet Andon lights and dashboard notifications ensure immediate action when gas levels exceed safe thresholds.

Data-Driven Hygiene Management

Cleaning schedules are now optimized based on live air quality data, reducing resource wastage.

Low Maintenance & Scalable

LoRaWAN-enabled devices operate long-term with minimal upkeep, allowing easy expansion to other warehouse zones.

Validation & Testing: Ensuring Reliable Air Quality Monitoring

Sensor Accuracy Verification

H₂S, NH₃, and CO₂ sensors were calibrated and tested to maintain ±2% measurement accuracy in varying humidity and temperature.

LoRaWAN Connectivity Testing

Long-range network coverage and data transmission were validated across all washrooms and service areas, ensuring zero communication gaps.

Alert System Validation

MacSet Andon lights and SCADA notifications were tested to confirm instant response when gas concentrations exceeded thresholds.

Integration Testing

End-to-end verification confirmed seamless synchronization between sensors, LoRaWAN gateway, and the facility’s SCADA dashboard.

Conclusion: Smarter Air Quality, Safer Workspaces

The deployment of LoRaWAN-enabled H₂S, NH₃, and CO₂ sensors with MacSync nodes and MacSet Andon lights transformed Amazon’s warehouse washrooms into data-driven, safe, and hygienic spaces.

This smart air quality solution demonstrates how IoT-powered monitoring can enhance safety, compliance, and operational efficiency in large industrial facilities.

Unlock the next real-world IoT deployment for Your Warehouse