Automating Remote Water Level Control

Efficient water management is a challenge when the source and the control point are miles apart. SVR Robotics, an automation company, faced this exact situation they needed to remotely monitor water levels and automatically control a valve motor located 2.5 km away, all while ensuring real-time reliability and zero manual intervention.

This is where Macnman Technologies stepped in, bringing the MacSync and MacSet system into action a seamless LoRa-based communication link that made remote automation possible even in signal-challenged industrial zones.

Problem: Disconnected PLCs Hindering Industrial Automation

SVR Robotics faced challenges in automating processes across two PLCs separated by 2 km in an industrial setup. Existing systems could not communicate reliably, causing delays and inefficiencies in valve and controller operations.

Disconnected Control Systems

PLCs could not exchange real-time data over long distances.

Manual Intervention Required

Operators had to monitor and trigger processes manually, slowing down operations.

Operational Inefficiency

Delays in data transfer led to suboptimal valve and controller performance.

Risk of Errors

Lack of automated communication increased the chance of human error in critical operations.

Proposed Solution: Smart LoRa-Based Water Level Automation System

To overcome the manual and disconnected process, Macnman Technologies and SVR Robotics collaborated to design a LoRa-based water level monitoring and valve control system powered by MacSync and MacSet controllers.

- 01

Real-Time Water Level Monitoring

MacSync node continuously measured and transmitted live water level data using LoRa communication.

- 02

MacSet PLC Integration

MacSet controller received LoRa data packets and communicated with the PLC over Modbus RTU for precise valve control.

- 03

Long-Range LoRa Connectivity

Reliable two-way communication between the tank and control unit over a 2.5 km line-of-sight range without dependency on Wi-Fi or SIM networks.

- 04

Automated Logic via PLC

PLC was programmed to automatically open or close the valve motor based on real-time water level thresholds received from the MacSet.

- 05

Integration Without System Change

Designed to integrate with existing infrastructure, requiring no hardware modifications to the valve or PLC system.

- 06

Integration with SCADA

All units are compatible with the existing SCADA systems ,no need to start over again from scratch

IoT Architecture for Smart Air Quality Monitoring

Deployment : Long-Range LoRa Communication Between MacSync & MacSet

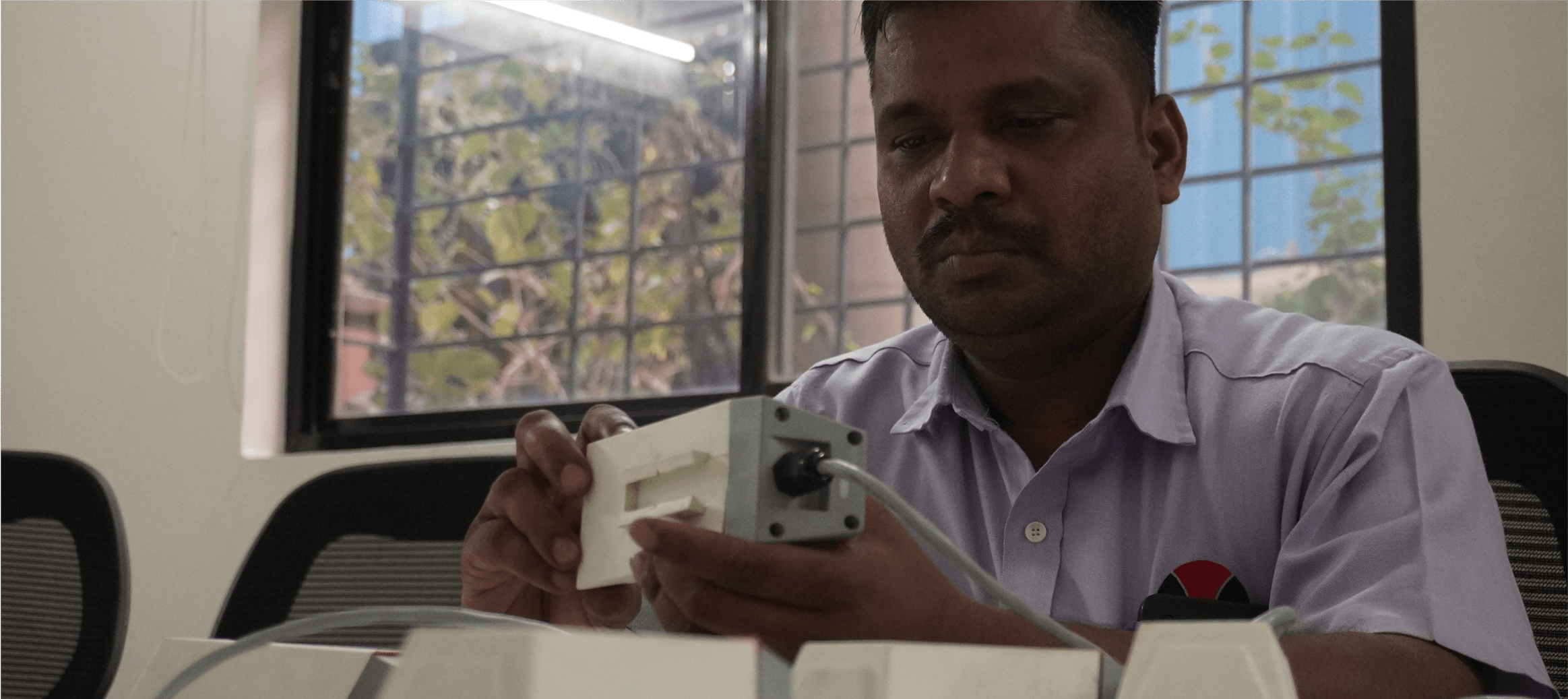

The system architecture was designed to enable reliable, long-distance communication between remote water level sensors and motor control units using LoRa technology.

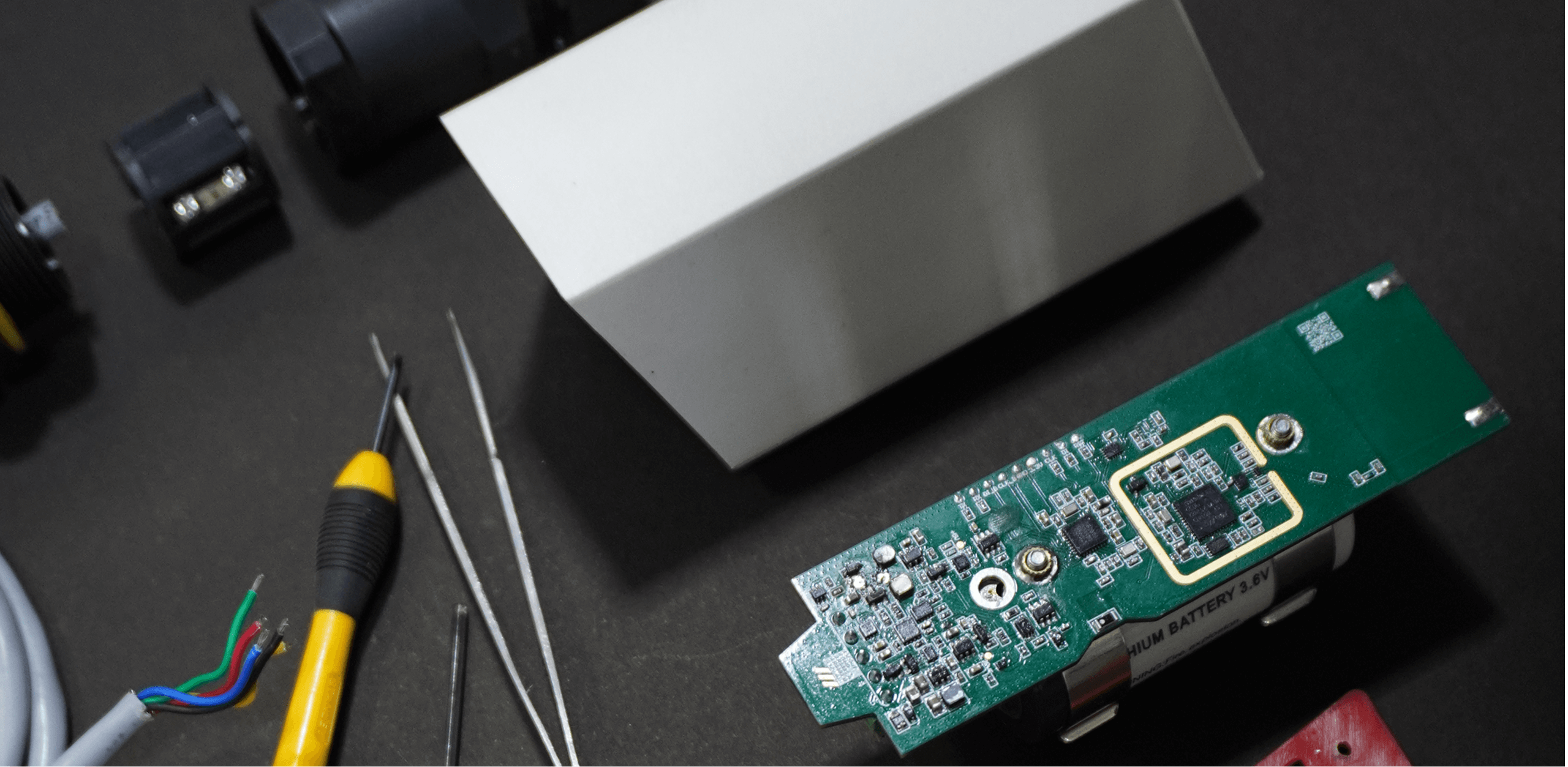

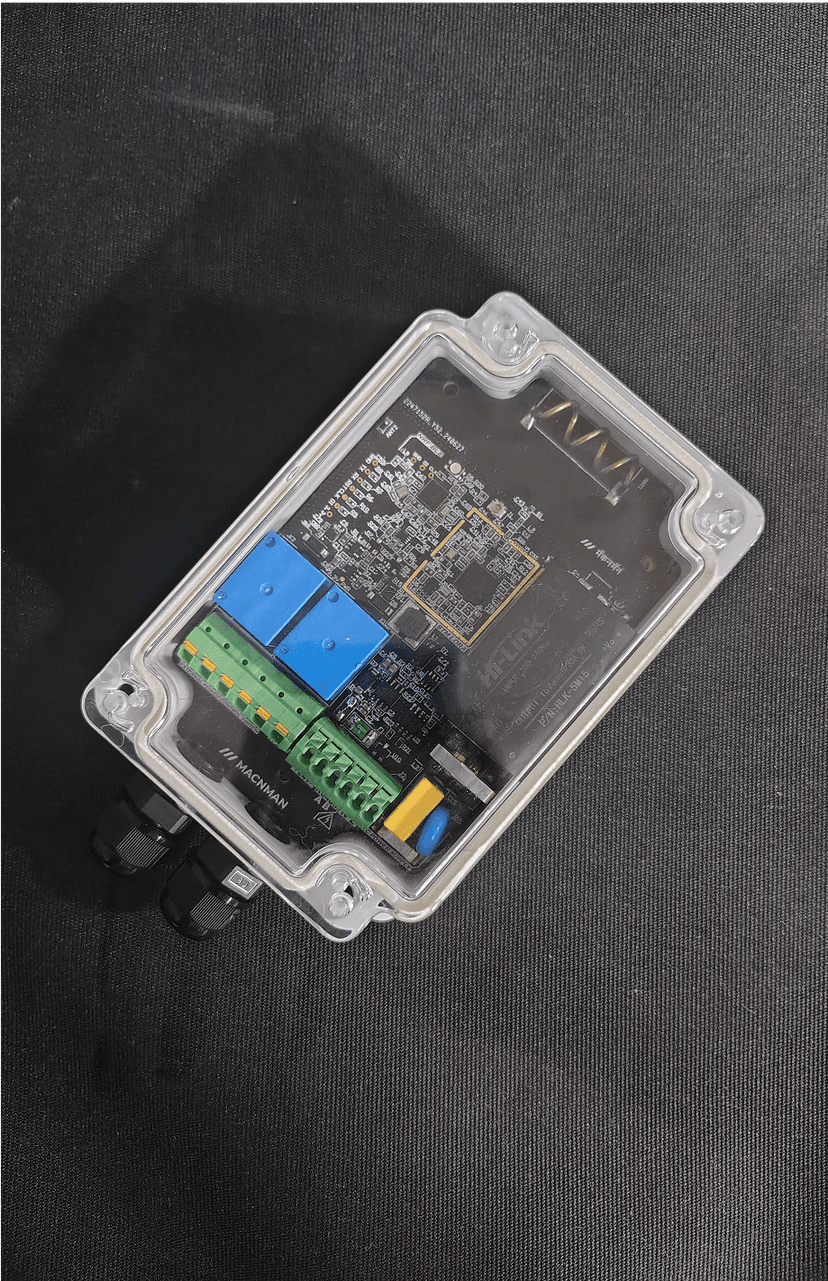

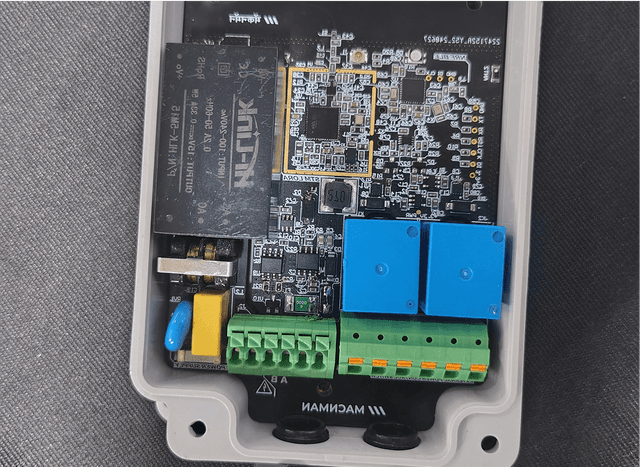

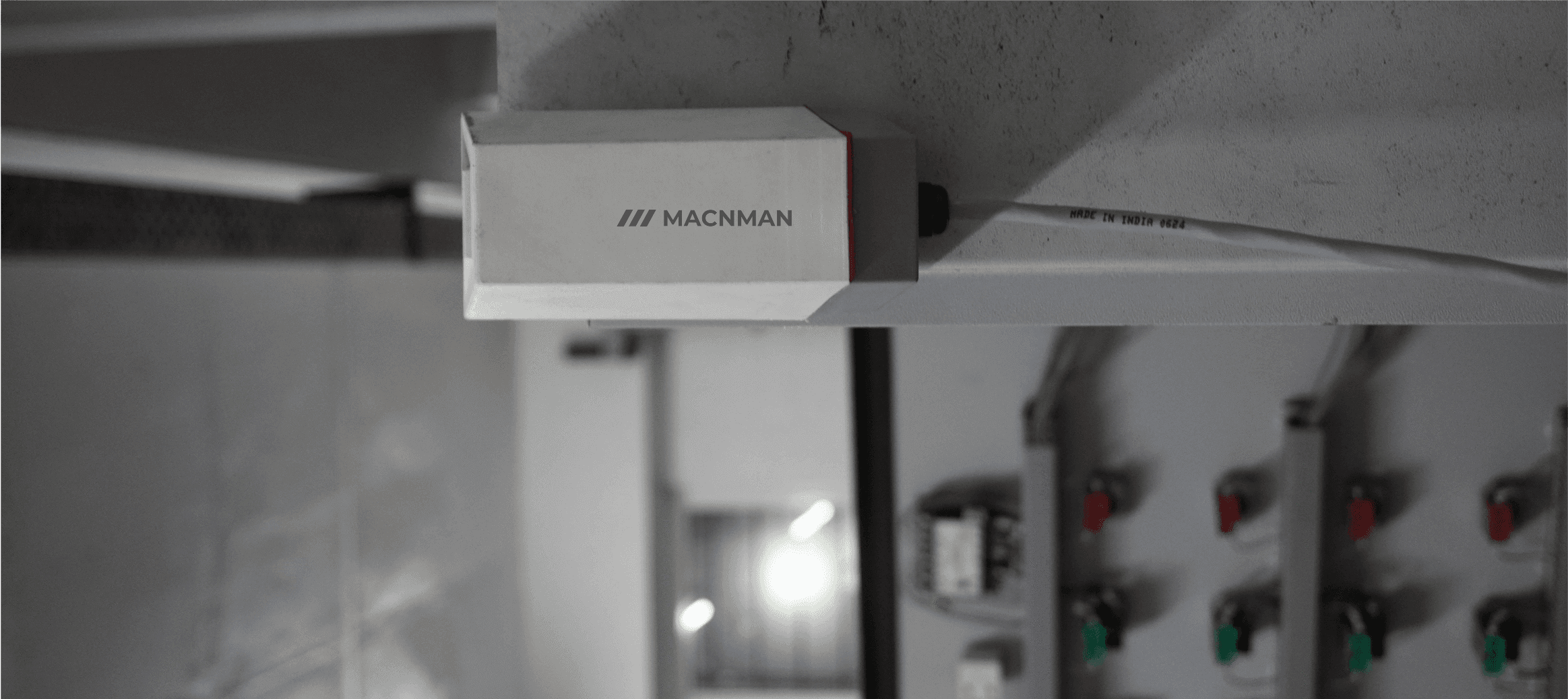

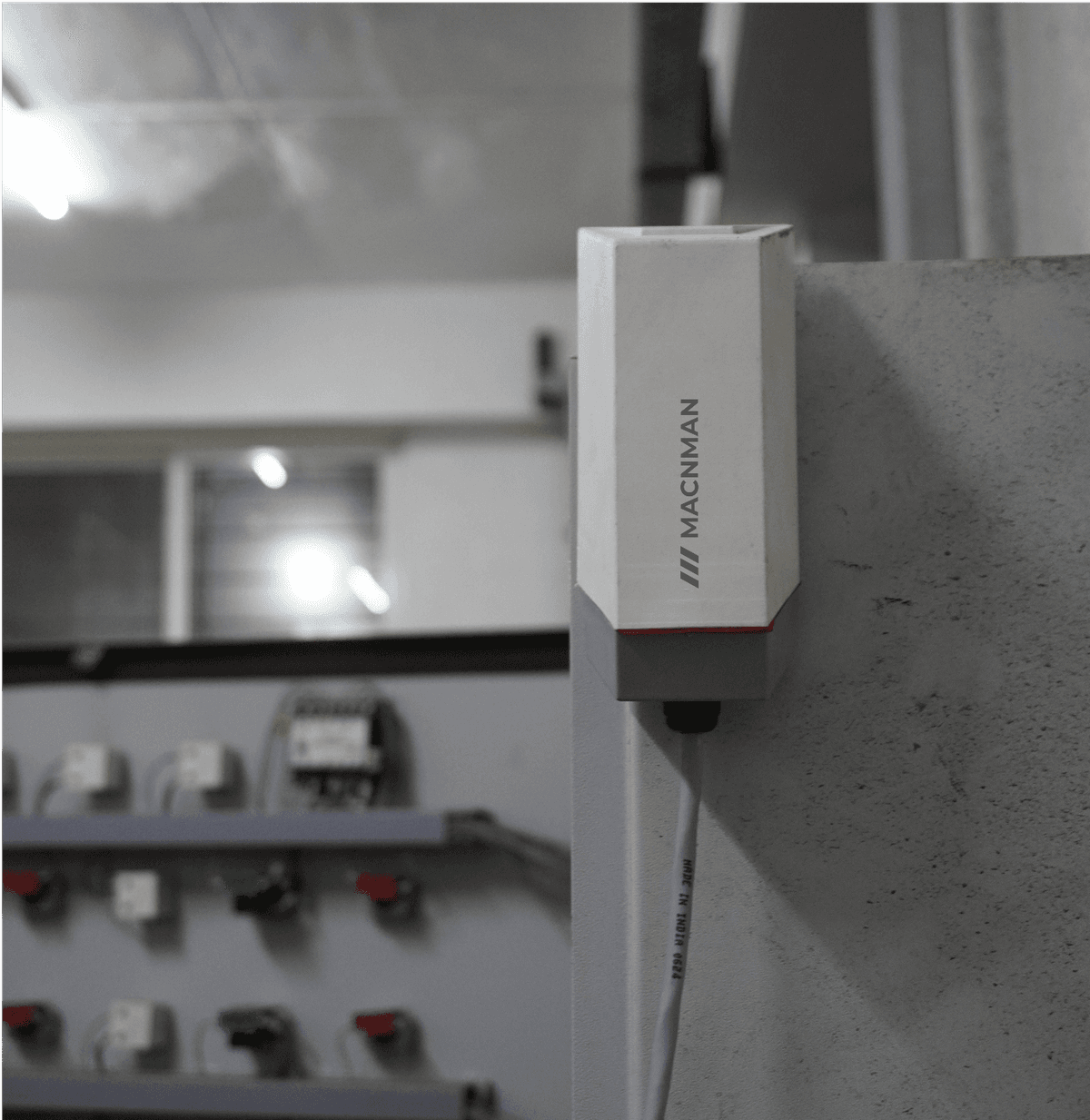

MacSync LoRaWAN Node

Installed at the tank location to capture accurate water level readings and transmit data via LoRa to the remote controller.

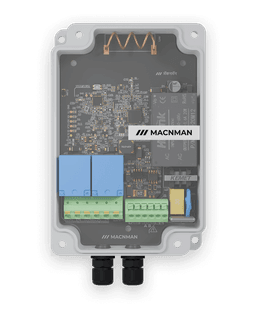

MacSet Controller

Deployed near the valve and motor control system to receive LoRa data from MacSync and communicate with the PLC through RS485 Modbus RTU.

SCADA Compatibility

The system architecture allows future integration with SCADA systems, enabling centralized monitoring and advanced data visualization.

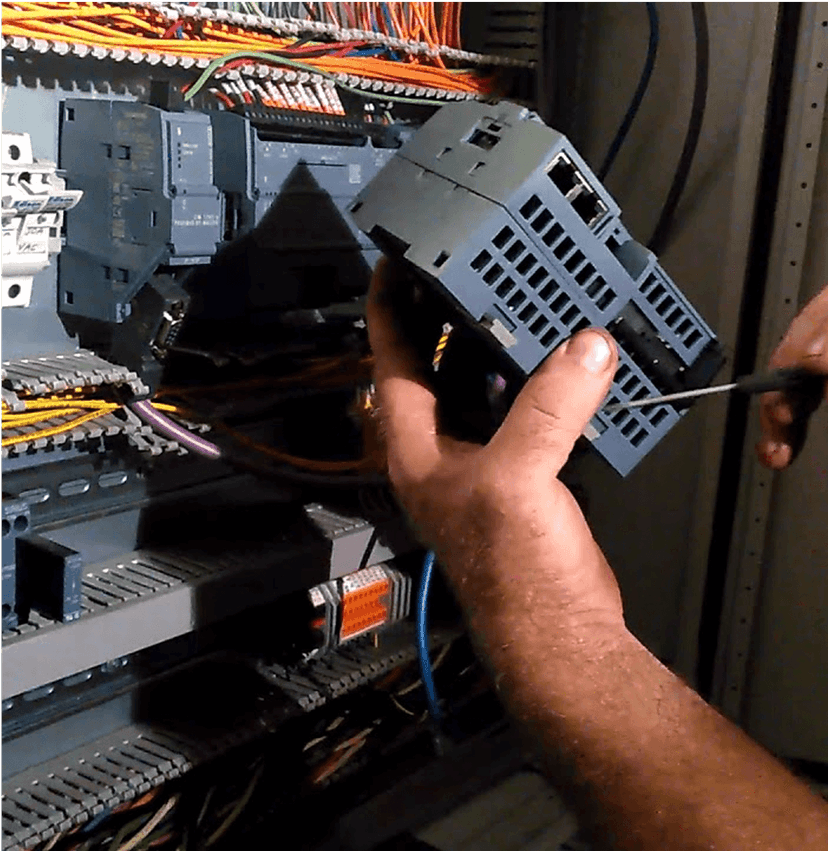

PLC Logic Integration

The PLC used the incoming data to decide when to start or stop the motor, automating the entire water flow control process.

Challenges: Achieving Reliable Long-Distance LoRa Communication

Line-of-Sight Limitations

The deployment area had partial obstructions like trees and uneven terrain, which made maintaining a stable LoRa signal challenging.

Signal Interference

The nearby industrial machinery introduced electrical noise, requiring precise antenna alignment and noise-resistant configuration.

PLC Communication Tuning

Ensuring seamless RS485 communication between the MacSet controller and the PLC required calibration and register mapping adjustments.

Weather-Resistant Setup

Both units had to operate reliably in outdoor industrial conditions, necessitating rugged enclosures and weatherproof installation.

Impact: Seamless Automation and Smarter Water Management

Automated Water Flow Control

The MacSync–MacSet link enabled automatic valve operation based on real-time tank levels, eliminating manual monitoring.

Reliable LoRa Communication

Achieved long-range connectivity through dense industrial terrain without cables or repeaters, ensuring uninterrupted data flow.

Energy and Resource Optimization

Reduced water wastage and pump running hours, translating to lower operational costs and energy savings.

Data Transparency for Maintenance

The system provided real-time data logs for predictive maintenance, improving response time and reducing downtime.

Testing & Validation: Ensuring Reliable Automation Over 2.5 km

Long-Range Connectivity Test

Verified stable LoRa P2P communication between the MacSync node at the tank and MacSet controller at the PLC over 2.5 km.

Sensor Accuracy Check

Ensured water level readings from the MacSync matched manual measurements for precise valve operation.

PLC Logic Validation

Tested automatic start/stop of the valve motor based on thresholds, confirming seamless PLC-MacSet integration.

End-to-End System Verification

Conducted multiple full-cycle tests, confirming real-time data transmission, motor control, and system reliability.

Conclusion: Reliable, Long-Range Automated Water Control

The deployment of MacSync and MacSet for SVR Robotics demonstrates how LoRa-based automation can transform remote water management.

- Efficient Automation: Eliminated manual monitoring and ensured precise valve control.

- Long-Range Reliability: Maintained seamless 2.5 km communication without internet or SIM dependency.

- Cost and Resource Savings: Optimized water usage and reduced operational overheads.

- Scalable Solution: Architecture allows future integration with SCADA or other industrial systems.

This project highlights how Macnman’s IoT solutions empower industrial operations to achieve smarter, safer, and more efficient workflows.

Unlock the next real-world IoT deployment for Your Warehouse