Cleaning Robots with LoRaWAN Connectivity

Maintaining large solar farms efficiently requires robots that can clean panels autonomously. However, sending commands to these robots and receiving their real-time cleaning status over long distances was a major challenge.

Macnman Technologies integrated LoRaWAN modules and gateways to enable seamless remote communication, allowing the robots to report their progress and receive control commands from the central server, ensuring optimized solar panel maintenance and improved energy output.

Problem: Limited Remote Connectivity for Solar Cleaning Robots

Maintaining large solar farms efficiently requires autonomous solar panel cleaning robots, but operators faced major challenges:

Disconnected Robot Operations

Robots couldn’t communicate with the central server over long distances, restricting remote control and automation.

Delayed Cleaning Monitoring

Lack of real-time status updates caused delays in identifying uncleaned panels or operational issues.

Inefficient Solar Farm Maintenance

Manual interventions were frequent, leading to missed cleaning schedules and reduced solar energy output.

Scalability Limitations

Expanding the robot fleet was challenging without a robust, long-range IoT communication system.

Proposed Solution: Seamless Remote Control with Macnman LoRaWAN

Macnman Technologies deployed LoRaWAN modules and gateways to establish a robust, long-range communication network for solar panel cleaning robots which is developed and supplied by our partner company. This solution enabled:

- 01

Real-Time Robot Status

Robots send live cleaning progress and operational data to the server.

- 02

Remote Command Execution

Servers can send downlink commands to control cleaning schedules and robot actions.

- 03

Automated Maintenance Insights

Operators gain actionable insights on panel cleanliness and robot performance.

- 04

Long-Range Connectivity

Reliable LoRaWAN communication ensures operations over kilometers of solar farms.

- 05

Scalable IoT Network

The system can support additional robots and integrate with other solar farm management tools.

- 06

Optimized Energy Output

Real-time monitoring and control ensure maximum solar panel efficiency and reduced downtime.

LoRaWAN Architecture for Downlinks

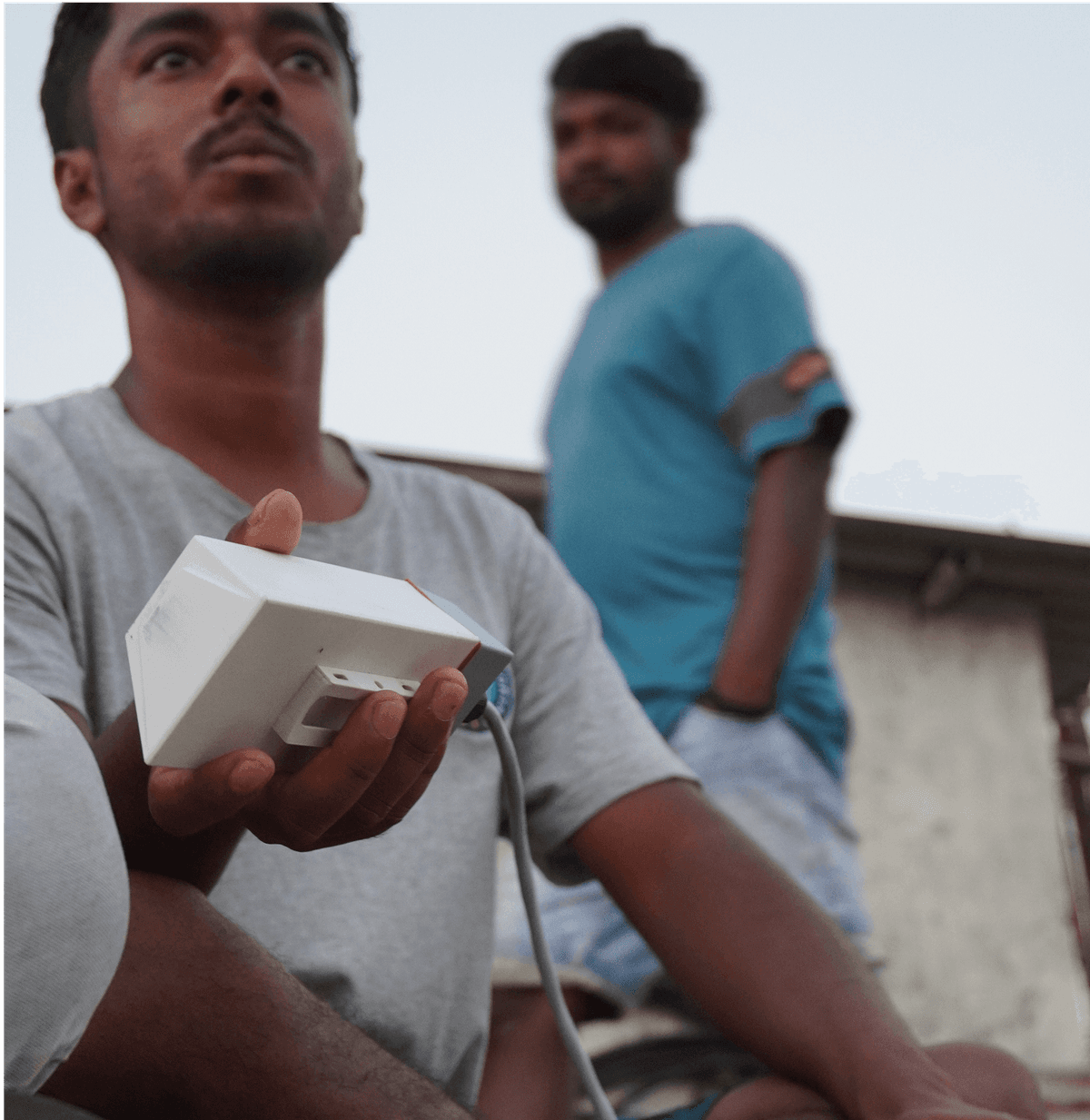

Deployment: LoRaWAN-Powered Solar Robot Communication Network

To enable seamless communication between the solar panel cleaning robots and the central control system, Macnman deployed a reliable and scalable LoRaWAN network consisting of the following components:

Macnman LoRaWAN Modules

Integrated directly into each cleaning robot’s control board to send live cleaning status and receive operation commands from the server.

Industrial LoRaWAN Gateways

Installed at strategic high points across the solar farm to ensure uninterrupted long-range communication, even across large open terrains.

SCADA Compatibility

The system architecture allows future integration with SCADA systems, enabling centralized monitoring and advanced data visualization.

PLC Logic Integration

The PLC used the incoming data to decide when to start or stop the motor, automating the entire water flow control process.

Challenges in Deploying LoRaWAN Communication for Solar Cleaning Robots

Wide Area Coverage

The solar farms spanned several kilometers, requiring optimized gateway placement to ensure strong signal coverage without creating communication blind spots.

Synchronization Between Robots and Server

Achieving perfect real-time synchronization between the cleaning robots’ controllers and the central cloud server was crucial for timely operation and feedback.

Downlink Latency Management

Managing downlink command latency—especially when multiple robots were operating simultaneously—was a key focus area to maintain smooth and reliable cleaning cycles.

Secure Data Communication

With remote operations, it was essential to prevent unauthorized access or false command triggers, so advanced encryption and authentication protocols were applied across all devices

Impact: Enhanced Industrial Automation with LoRaWAN PLC Integration

Seamless Remote Operations

Operators could now send cleaning commands remotely from the control room, drastically reducing the need for on-site manual intervention.

Real-Time Cleaning Insights

The cleaning robots continuously sent status updates, allowing operators to monitor performance, detect anomalies, and track completion progress in real-time.

Enhanced Operational Efficiency

Automated cleaning schedules and instant response from the robots helped optimize energy output and reduce panel downtime.

Scalable and Future-Ready Setup

The modular architecture designed by Macnman allows easy expansion across multiple solar sites—supporting hundreds of robots under one unified network.

Testing & Validation: Reliable LoRaWAN Performance for Solar Cleaning Robots

Long-Range Testing

Verified seamless connectivity up to 6 km across large solar farms.

Zero Packet Loss

Ensured accurate uplink and downlink data transmission for command reliability.

Real-Time Response

Confirmed instant command execution and status updates from robots.

Environmental Endurance

Tested performance under high heat, dust, and reflective panel surfaces

Tested performance under high heat, dust, and reflective panel surfaces

Through this deployment, Macnman Technologies successfully enabled reliable LoRaWAN-based communication between solar cleaning robots and the central control system. The seamless uplink and downlink connectivity allowed real-time command execution, cleaning status updates, and maintenance insights — all without manual intervention.

This solution not only improved operational efficiency but also laid the foundation for fully automated, energy-efficient solar farms, showcasing how Macnman’s IoT expertise drives the future of smart renewable systems.

Discover the Power of Macnman LoRaWAN Modules in Real-World Deployments