Industrial Lighting Automation

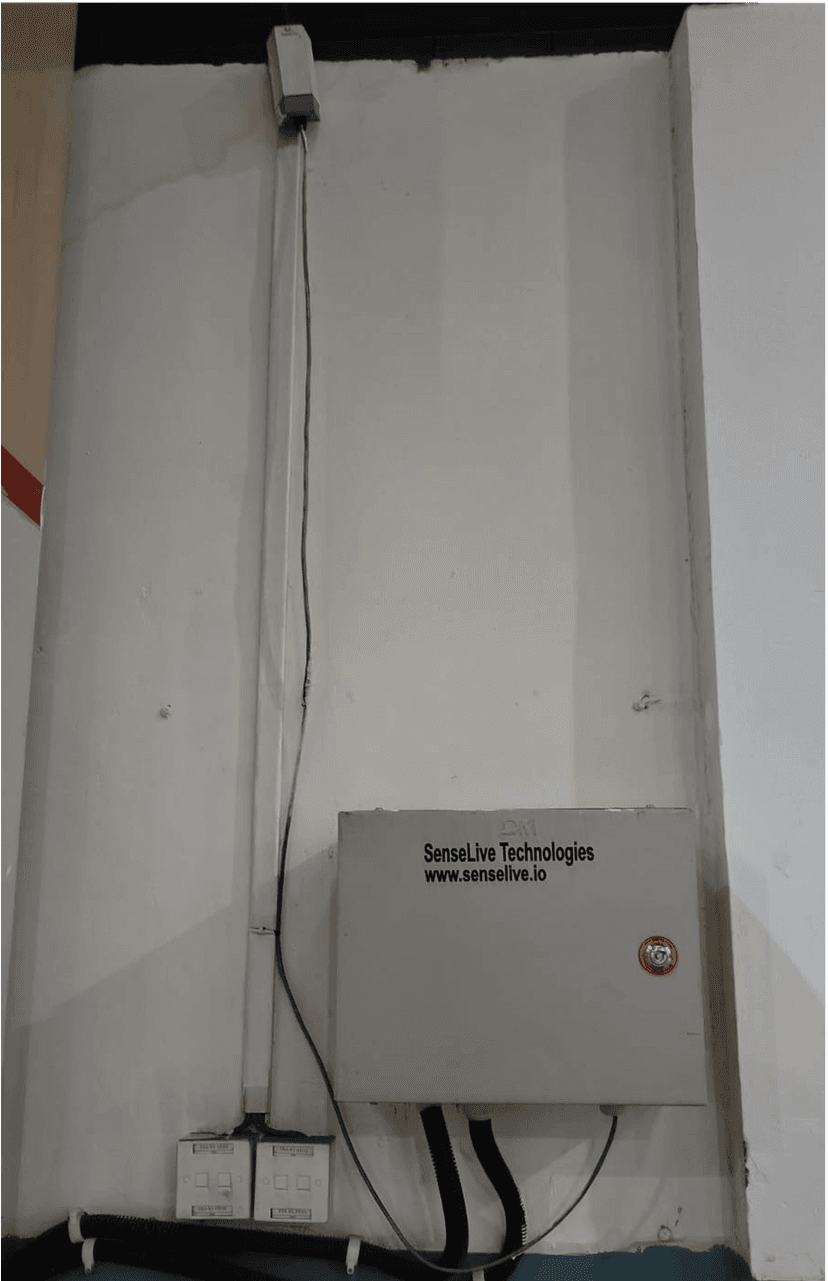

In collaboration with Senselive, we deployed MacSync RS485 nodes at CEAT Tyres to remotely control 32-channel Modbus-enabled relay boards, enabling automated lighting control across the plant. This solution eliminated manual intervention, improved energy efficiency, and integrated seamlessly with their existing infrastructure.

Problem: Manual Lighting Control & Inefficiency

CEAT Tyres faced challenges with controlling industrial lighting across multiple zones using traditional manual methods

Time-Consuming Operations

Manual switching of lights and controllers caused delays and operational inefficiency.

Energy Wastage

Lights often remained on unnecessarily, increasing energy costs and carbon footprint.

Integration Challenges

Existing lights systems were not remotely controllable, limiting automation capabilities.

Limited Visibility & Control

Plant managers had no real-time oversight of lighting status, leading to reactive decision-making.

Proposed Solution: LoRaWAN RS485 Modbus 32 Channel Controlling

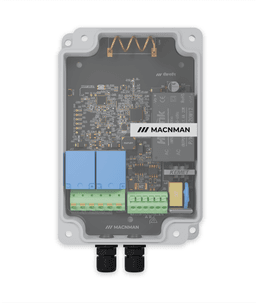

Macnman Technologies, in collaboration with Senselive, deployed a LoRaWAN-based solution to remotely control CEAT Tyres’ 32-channel relay boards:

- 01

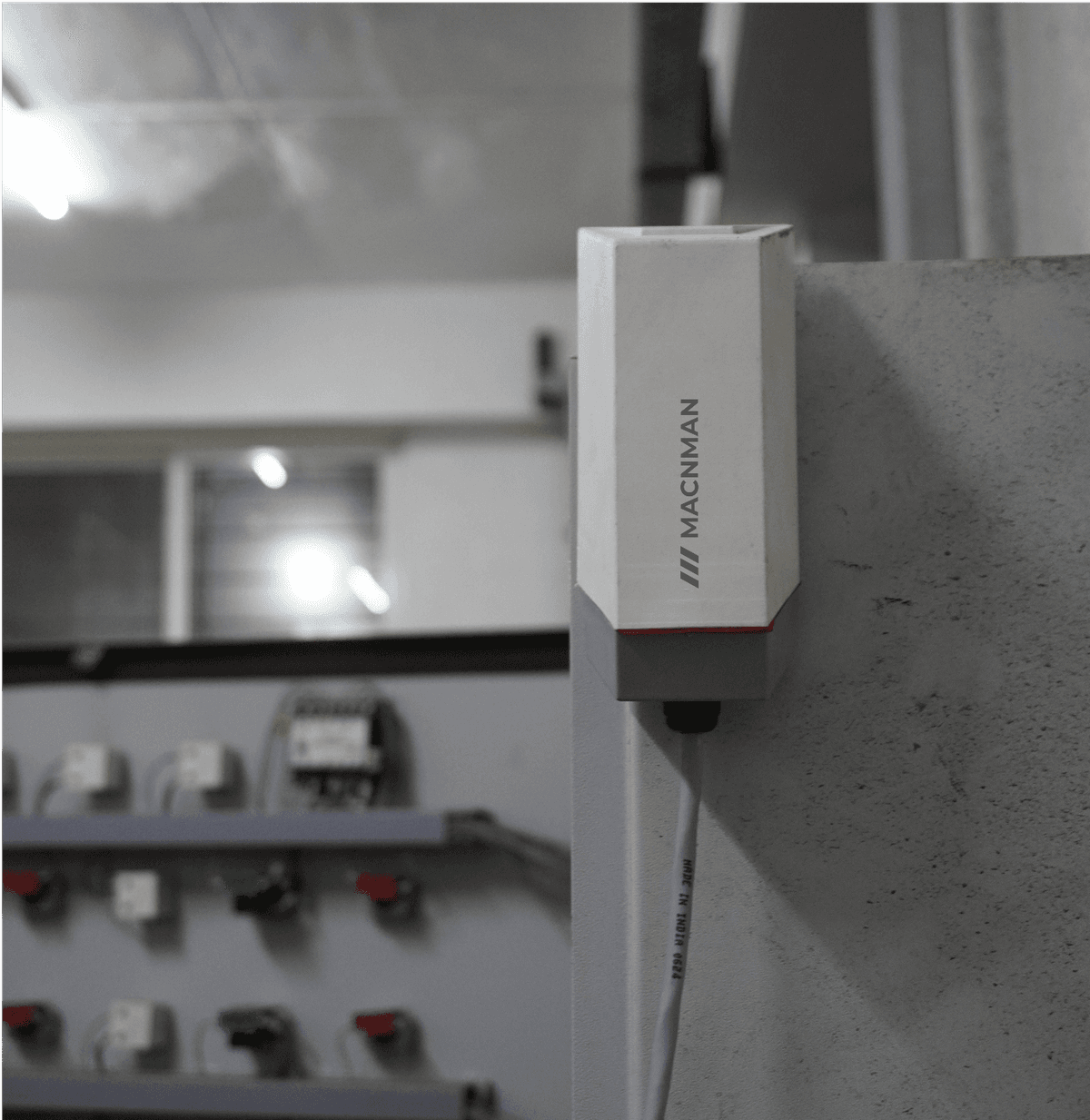

MacSync RS485 Nodes

Configured to write RS485 registers and control individual relays remotely.

- 02

Seamless Modbus Integration

Connected with existing Modbus-enabled relay boards without modifying the infrastructure.

- 03

LoRaWAN Connectivity

Enabled long-range, low-power wireless communication across the industrial plant.

- 04

Centralized Control Dashboard

Plant managers gained real-time visibility and control over all lighting zones.

- 05

Automated Scheduling

Lights could now be switched on/off or dimmed based on operational schedules.

- 06

Energy Optimization

Remote control and automation reduced energy wastage and lowered operational costs.

System Architecture: LoRaWAN-Based Smart Drainage Automation Network

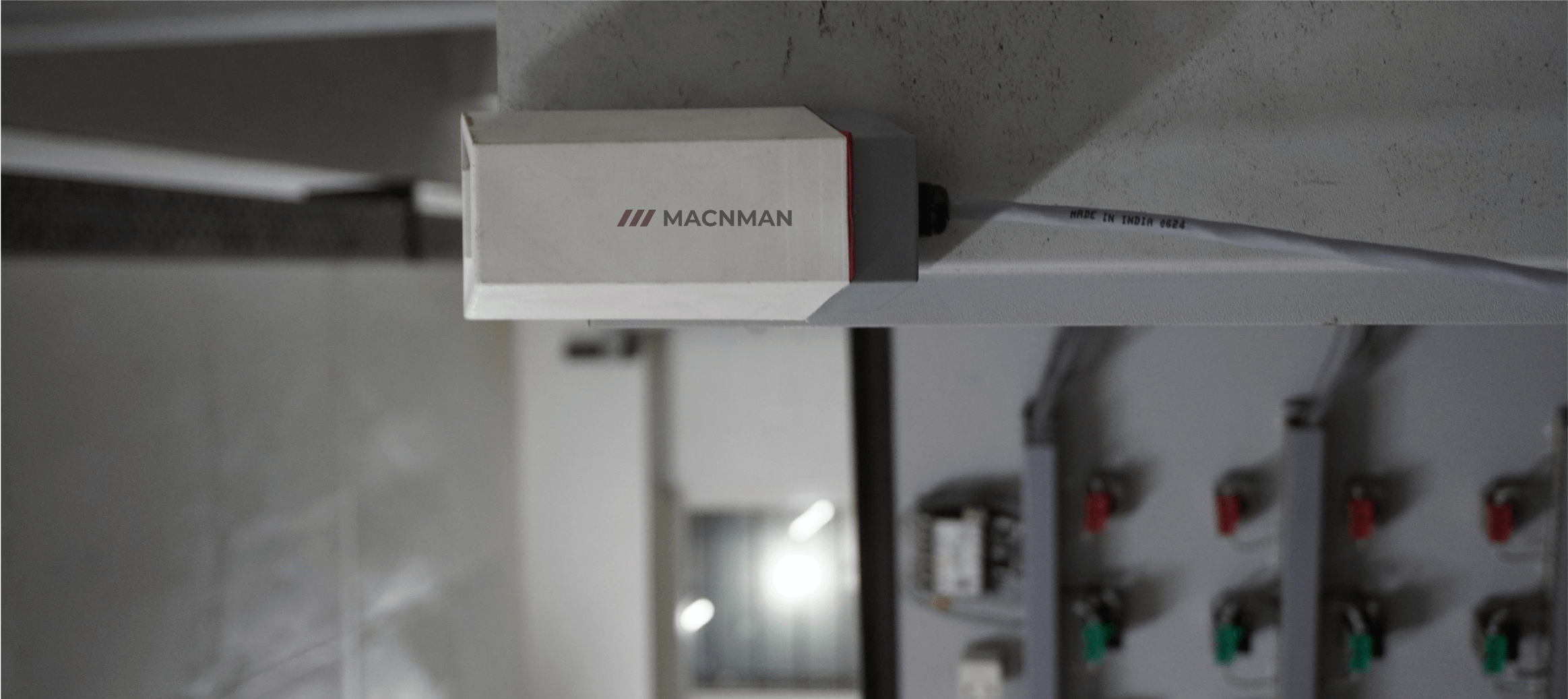

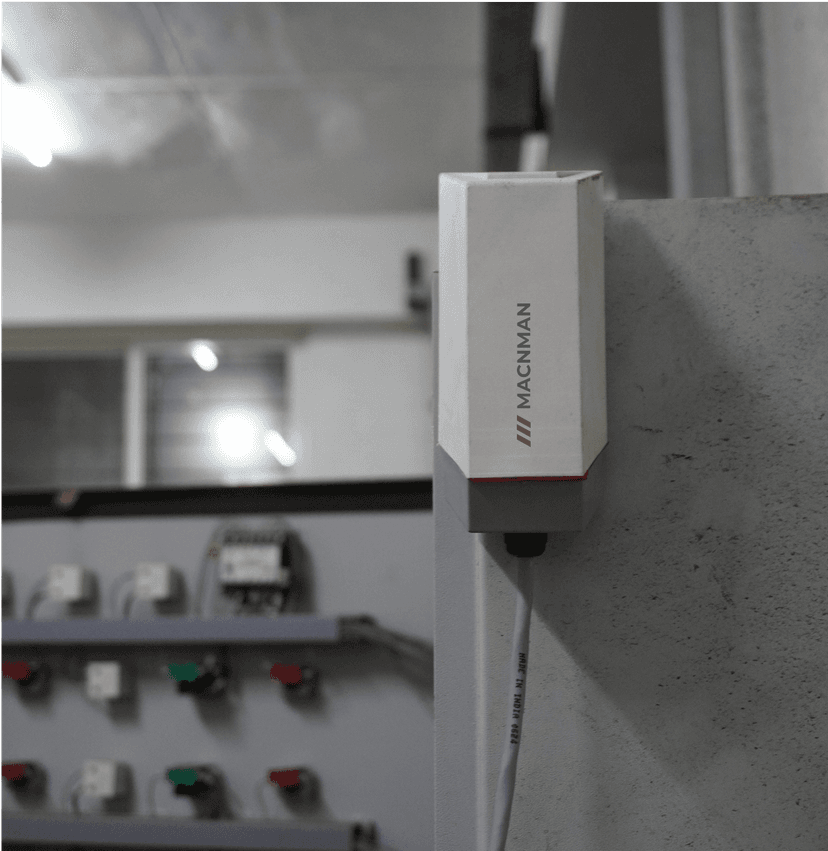

Deployment Overview: Smart Drainage System in Action

The deployment of Macnman’s ultrasonic water level monitoring and pump automation system was designed to cover every critical point in the industrial plant’s underground drainage network.

MacSync RS485 Nodes

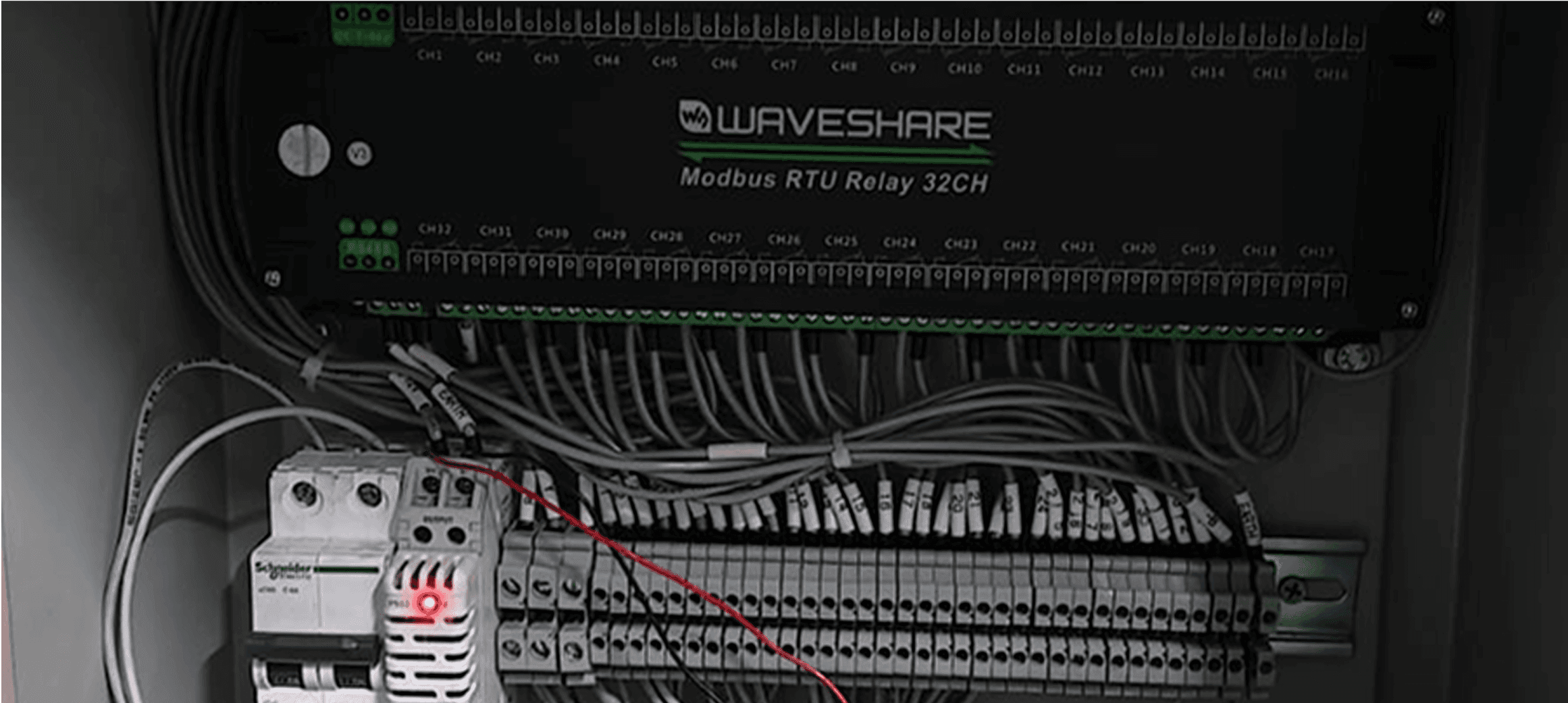

Configured to write to RS485 registers on the 32-channel relay boards, enabling remote control of lights.

Industrial LoRaWAN Gateway

Provided long-range, low-power connectivity, linking all nodes to the central control system.

Waveshare 32 channel Relay Boards

32-channel relay boards, enabling remote control of light using the MacSync.

Central Dashboard & Controller

Allowed real-time monitoring, relay status checks, and automated lighting schedules for all zones.

Deployment Challenges: Reliable LoRaWAN Industrial Lighting Control

Complex RS485 Modbus Integration

Configuring MacSync RS485 nodes to communicate with 32-channel Modbus-enabled relay boards required precision for seamless industrial IoT control.

LoRaWAN Signal Interference

Dense metal structures and machinery caused potential communication issues, solved with optimized gateway placement and high-gain antennas.

Scalable Node Management

Managing multiple industrial lighting zones demanded efficient node configuration, monitoring, and network reliability.

Low-Latency Real-Time Control

Instant response for lighting commands across the plant required a robust LoRaWAN network and fast data transmission.

Impact: LoRaWAN IoT Lighting Automation for Smart Factories

Remote Industrial Lighting Control

Enabled real-time control of 32-channel RS485 Modbus relay boards, reducing manual intervention and improving plant efficiency.

Significant Energy Savings

Automated schedules and remote switching lowered electricity consumption and reduced operational costs.

Real-Time Operational Visibility

Central dashboards provided instant insights into lighting status across the factory for data-driven management.

Scalable Smart Factory Solution

LoRaWAN network allows future expansion, supporting additional lighting zones or other plant automation systems.

Validation: Ensuring Reliable Industrial Lighting Automation

RS485 Communication Verification

Tested MacSync nodes writing to Modbus registers for all 32-channel relay boards to ensure accurate command execution.

LoRaWAN Network Stability

Validated long-range, low-power connectivity across the plant, ensuring consistent, real-time control.

Operational Stress Testing

Continuous monitoring over multiple weeks ensured system stability, minimal downtime, and scalability.

Automated Schedule Testing

Simulated lighting schedules and automated triggers to confirm energy-efficient operation.

Conclusion: Smart IoT Lighting for Energy-Efficient Factories

The deployment of MacSync RS485 nodes with LoRaWAN connectivity transformed CEAT Tyres’ industrial lighting system

Seamless remote control of 32-channel relay boards improved operational efficiency.

Energy optimization through automated schedules reduced electricity costs.

Real-time visibility enabled proactive plant management and decision-making.

Scalable IoT solution supports future expansions and additional automation.

This case demonstrates how industrial IoT solutions can deliver smart, energy-efficient, and fully automated lighting control for modern factories.

Explore more industrial IoT success stories