IoT-Powered Drainage Monitoring

Industrial plants often face a hidden threat beneath their floors clogged underground drainage systems. When water levels rise undetected, it can lead to equipment downtime, material damage, and operational disruptions, especially during heavy rainfall or cleaning cycles.

To tackle this challenge, Macnman Technologies deployed an IoT-powered ultrasonic water level monitoring system designed specifically for industrial drainage networks. Using MacSync LoRaWAN Controllers, long-range gateways, and industrial-grade ultrasonic sensors, the system delivers continuous, real-time insights on underground water levels without requiring manual checks.

The Problem: Hidden Flood Risks Beneath the Plant

Even in well-managed industrial facilities, underground drainage systems are often overlooked until a serious problem surfaces. Manual inspection methods were unreliable, slow, and unsafe for maintenance teams — leading to delayed responses and unpredictable outcomes.

Blocked Drains

Sediment buildup and industrial waste caused unexpected clogs, leading to water overflow and flooding during cleaning or rainfall.

Manual Monitoring

Maintenance teams had to physically open chambers to check water levels — time-consuming, risky, and inconsistent.

No Real-Time Visibility

Without continuous monitoring, drainage health could only be guessed, not measured.

Safety Concerns

Standing water near power units and control panels created electrical hazards and unsafe working conditions.

Proposed Solution: Smart Water Level Monitoring & Automated Pump Control with LoRaWAN

To solve the recurring drainage overflow issues, we introduced a fully automated IoT solution that not only monitors underground water levels but also activates pumps automatically based on real-time sensor data.

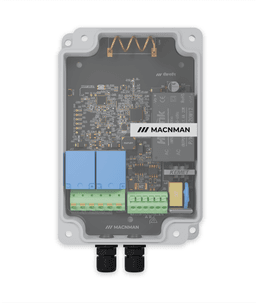

The integration of Ultrasonic Sensors, MacSet LoRaWAN Controllers, and intelligent logic control ensures uninterrupted operations and proactive flood prevention — all without manual intervention.

- 01

Ultrasonic Water Level Sensors

Industrial-grade ultrasonic sensors detect the exact water depth in underground drainage chambers, unaffected by debris, foam, or humidity.

- 02

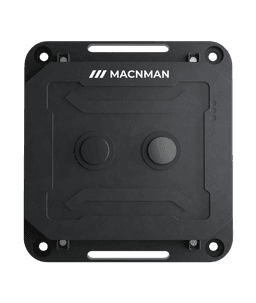

MacSet LoRaWAN Controller

Each controller receives sensor data and triggers the connected pumps automatically when the water level crosses a defined threshold.

- 03

Automated Pump Activation

Smart logic ensures pumps start and stop precisely when needed — preventing both overflow and dry running, optimizing energy use.

- 04

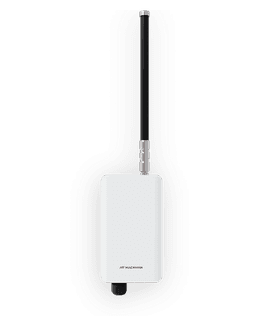

LoRaWAN Gateway Connectivity

All controllers communicate wirelessly to a central LoRaWAN gateway, which sends real-time status updates to the cloud dashboard

- 05

Real-Time Alerts

Supervisors get instant notifications when pumps activate, water levels rise abnormally, or any fault occurs in the drainage system

- 06

Maintenance Planning

Continuous data logging helps identify trends enabling predictive maintenance, early detection of partial blockages, and better pump lifecycle management.

System Architecture: LoRaWAN-Based Smart Drainage Automation Network

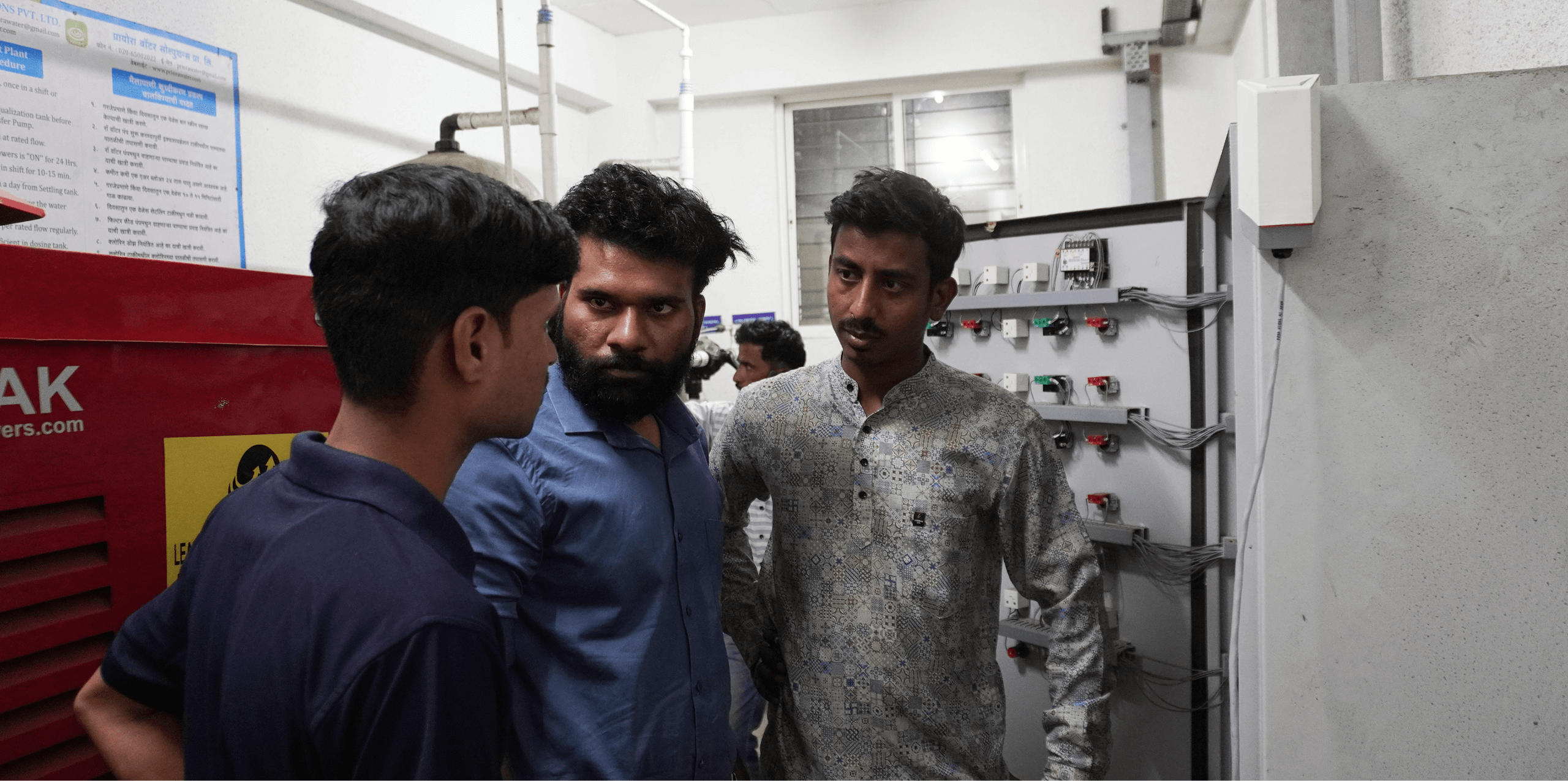

Deployment Overview: Smart Drainage System in Action

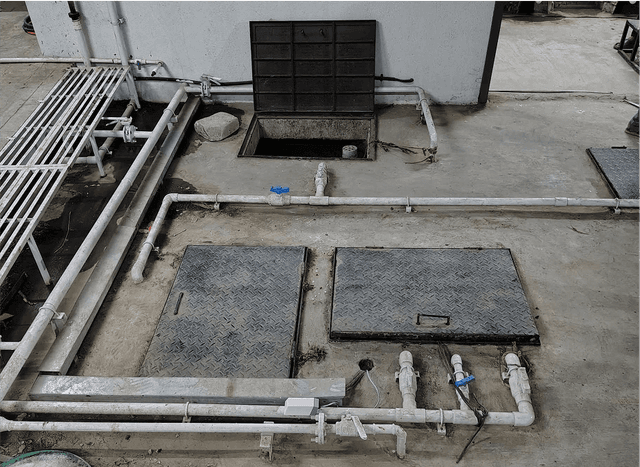

The deployment of Macnman’s ultrasonic water level monitoring and pump automation system was designed to cover every critical point in the industrial plant’s underground drainage network.

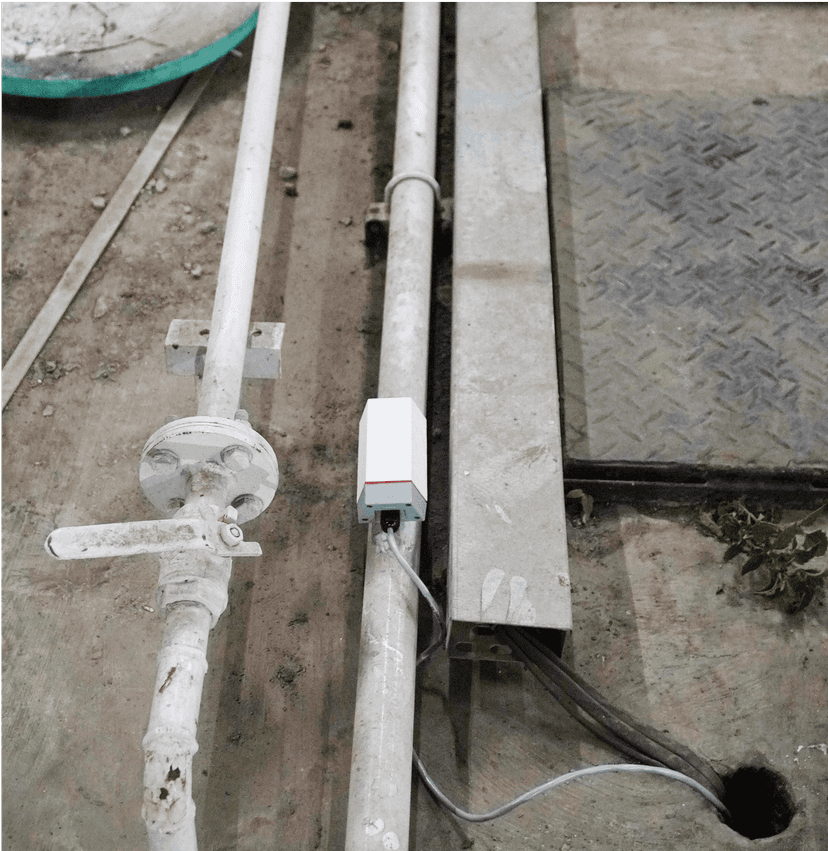

Ultrasonic Sensors

Installed inside each drainage chamber and sump pit , Positioned to avoid debris accumulation and ensure precise water level readings.

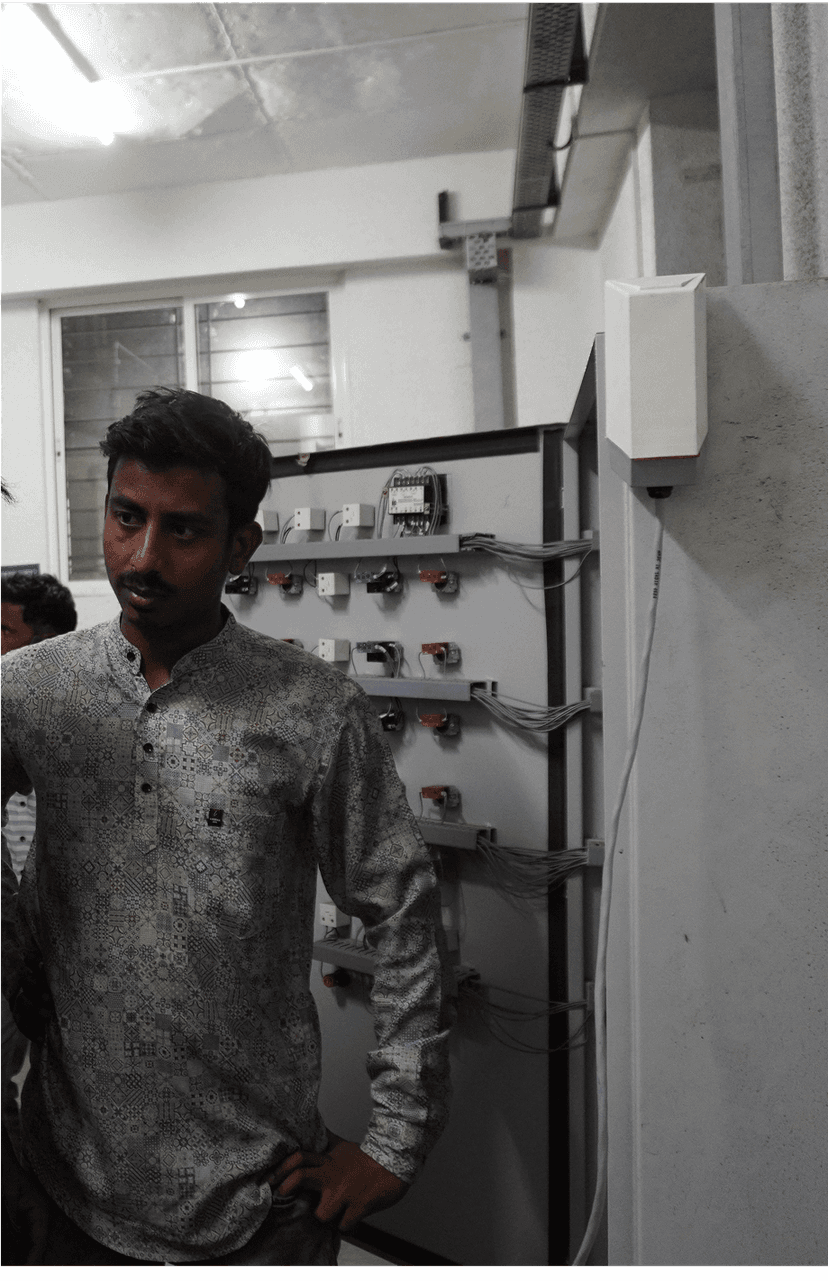

LoRaWAN Gateway

Centralized location in the plant ensures long-range, interference-free communication with all controllers.

Relays data to the dashboard/server for monitoring and alerting.

MacSet LoRaWAN Controllers

Mounted near pump stations or accessible control points.

Each controller manages multiple sensors and triggers pumps automatically.

Monitoring Dashboard

Displays live water levels, pump status, and historical trends. Sends automated alerts to supervisors via app, SMS, or email.

Deployment Challenges: Overcoming Industrial Drainage Hurdles

Connectivity Gaps 📡

Thick walls, metallic structures, and underground chambers created signal interference.

Harsh Environment 🌦️

Industrial-grade ultrasonic sensors and IP67-rated enclosures guaranteed continuous operation without damage.

Pump Control Precision ⚙️

Incorrect water level thresholds or delayed pump activation could lead to flooding or energy waste.

Sensor Placement Accuracy 🎯

Incorrect positioning in pits caused false readings due to turbulence, foam, or shadows. Each sensor was field-mapped and calibrated for consistent accuracy.

Impact: Smarter Flood Prevention in Industrial Drainage

Prevented Overflow & Flooding 🌊

Real-time monitoring and automated pump control eliminated water buildup, reducing operational downtime.

Operational Efficiency Boost ⚡

Automatic pump activation cut manual intervention, saving maintenance labor hours and ensuring uninterrupted workflow.

Energy Optimization 🔋

Pumps operate only when needed, reducing unnecessary electricity consumption by up to 25%.

Improved Safety 🛡️

Early detection of rising water levels prevented equipment exposure and workplace hazards.

Predictive Maintenance Enabled 🛠️

Continuous water level logging helps identify potential drainage blockages before they become critical, reducing emergency repairs.

Testing & Validation: Ensuring Accuracy and Automated Control ✅

Sensor Calibration 🎯

Each ultrasonic sensor was calibrated to accurately measure water levels in confined underground chambers, accounting for turbulence, foam, and debris.

Connectivity Verification 📡

LoRaWAN controllers and gateways were stress-tested to ensure reliable, long-range communication in dense industrial environments.

Pump Activation Testing ⚙️

Controllers were tested under varying water levels to confirm precise, automated pump operation, preventing overflow and avoiding dry running.

Durability & Environmental Testing 🌦️

Sensors and controllers were exposed to high humidity, occasional chemical exposure, and dust to validate IP67-rated reliability in industrial conditions.

Conclusion: Automated Flood Prevention for Industrial Plants

Macnman’s LoRaWAN-based ultrasonic water level monitoring and pump automation system transformed the industrial plant’s underground drainage network from a hidden risk into a fully controlled, proactive system.

By combining industrial-grade ultrasonic sensors, MacSync LoRaWAN controllers, and smart gateway connectivity, Macnman delivered a reliable, low-power, and automated flood prevention solution — safeguarding equipment, reducing downtime, and optimizing plant operations.

Read the Next Case Study: Vehicle performance in Mines