LoRaWAN Datalogger for Vacuum Pressure

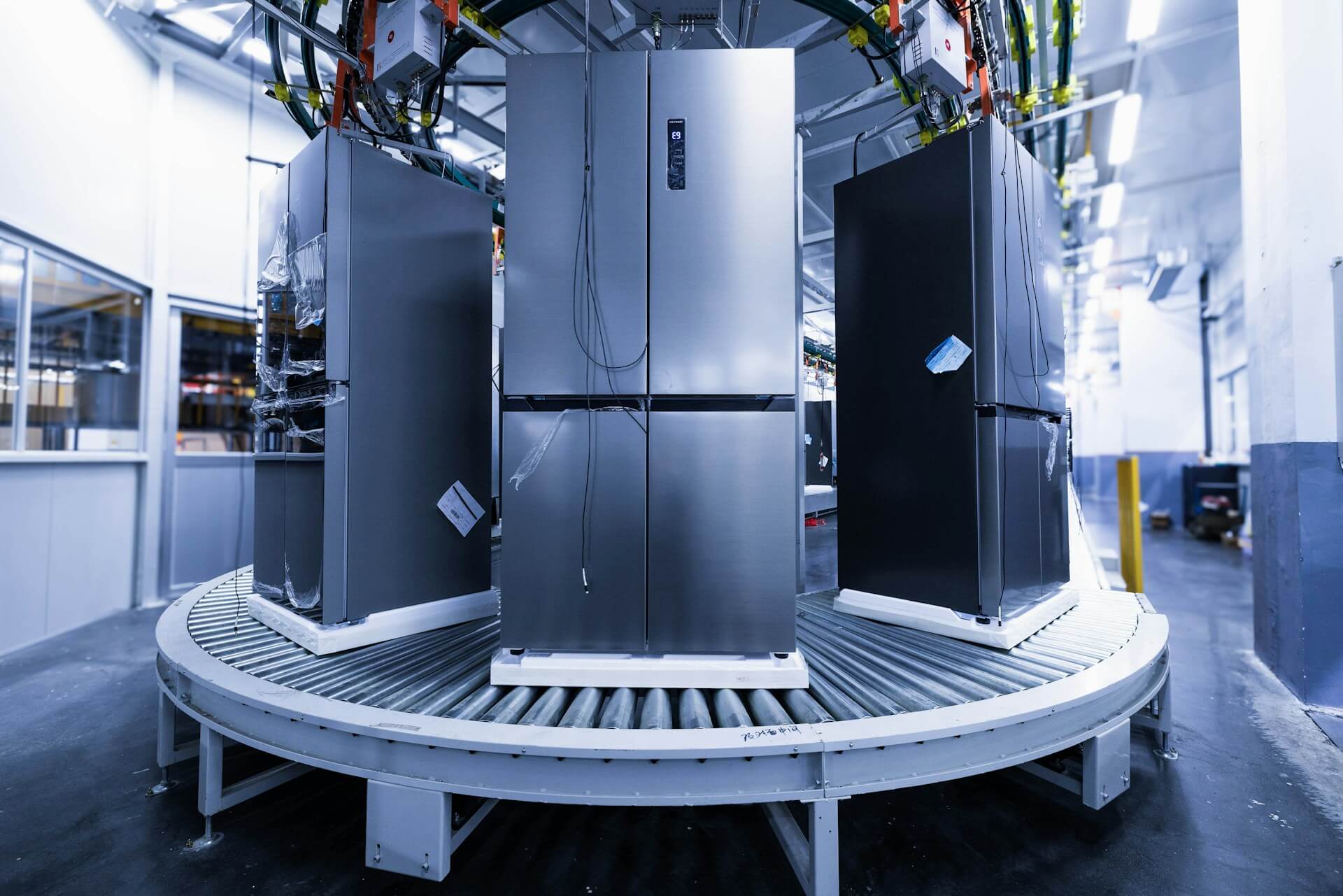

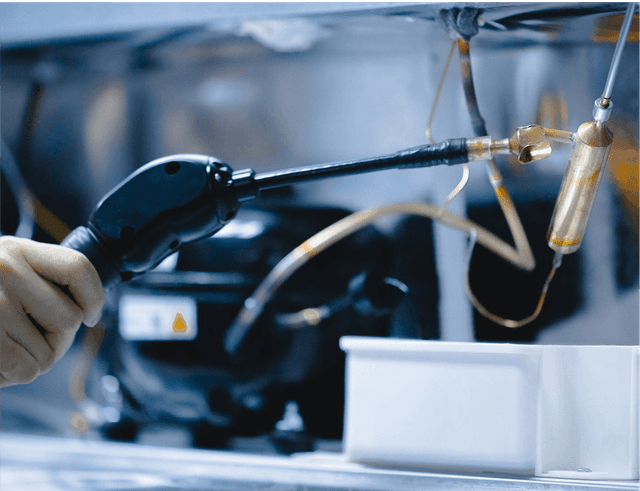

A leading refrigerator manufacturer needed centralized, real-time monitoring of vacuum pressure across multiple production lines. Their existing gauges worked well locally but lacked remote visibility and actionable data.

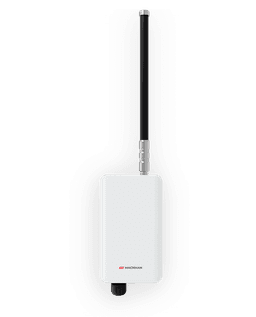

Macnman Technologies deployed MacSync Series RS485-to-LoRaWAN Data Loggers, which captured readings from the installed vacuum pressure gauges and transmitted them securely to the customer’s SCADA system.

This solution allowed engineers to analyze trends, detect anomalies, and trigger automated actions, all without changing the existing equipment or disrupting production.

The Challenge: Data Gaps and Delayed Action ⚠️

Even with high-quality vacuum pressure gauges installed, the manufacturer faced several operational hurdles. The goal was clear — bridge the existing RS485 gauges to a LoRaWAN network, enabling real-time monitoring, SCADA integration, and actionable insights without changing the installed equipment.

Siloed Data

Each gauge collected readings locally, with no centralized visibility across production lines.

Delayed Responses

Manual checks or periodic data downloads meant late detection of anomalies, risking equipment or product quality.

Limited Integration

Existing gauges were not connected to SCADA, making automated analysis and action impossible

Maintenance Complexity

Without remote monitoring, engineers had to physically inspect each gauge, increasing labor and downtime.

Proposed Solution: RS485-to-LoRaWAN Data Logging 📡

To solve the monitoring and integration challenges, Macnman Technologies deployed the MacSync Series RS485-to-LoRaWAN Data Loggers across all production lines.

- 01

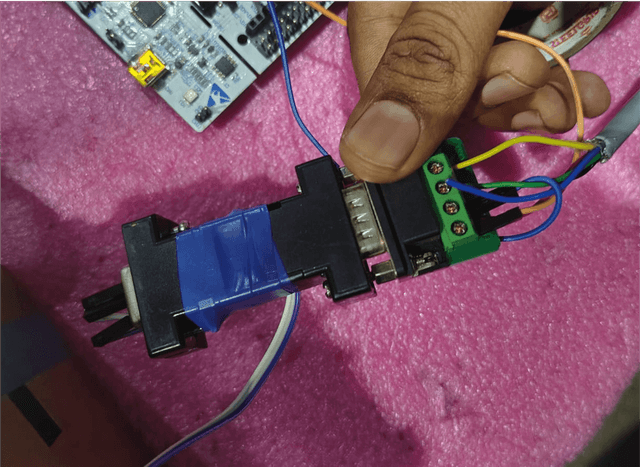

Seamless RS485 Integration

Connected directly to the existing vacuum pressure gauges without modifying hardware.

- 02

Long-Range LoRaWAN Transmission

Transmitted gauge readings wirelessly to the central SCADA system, covering the facility reliably.

- 03

Real-Time Data Access

Enabled engineers to monitor pressure trends instantly and respond to anomalies immediately.

- 04

SCADA System Integration

Data was fed directly into the customer’s existing SCADA dashboards for automated visualization and analysis.

- 05

Non-Intrusive Deployment

Installation required minimal downtime, keeping production uninterrupted.

- 06

Scalable & Future-Ready

Additional gauges or lines can be integrated into the LoRaWAN network without new wiring or infrastructure changes.

LoRaWAN Architecture for Green-house Automation

FreshMart’s IoT Sensor Deployment 🌱

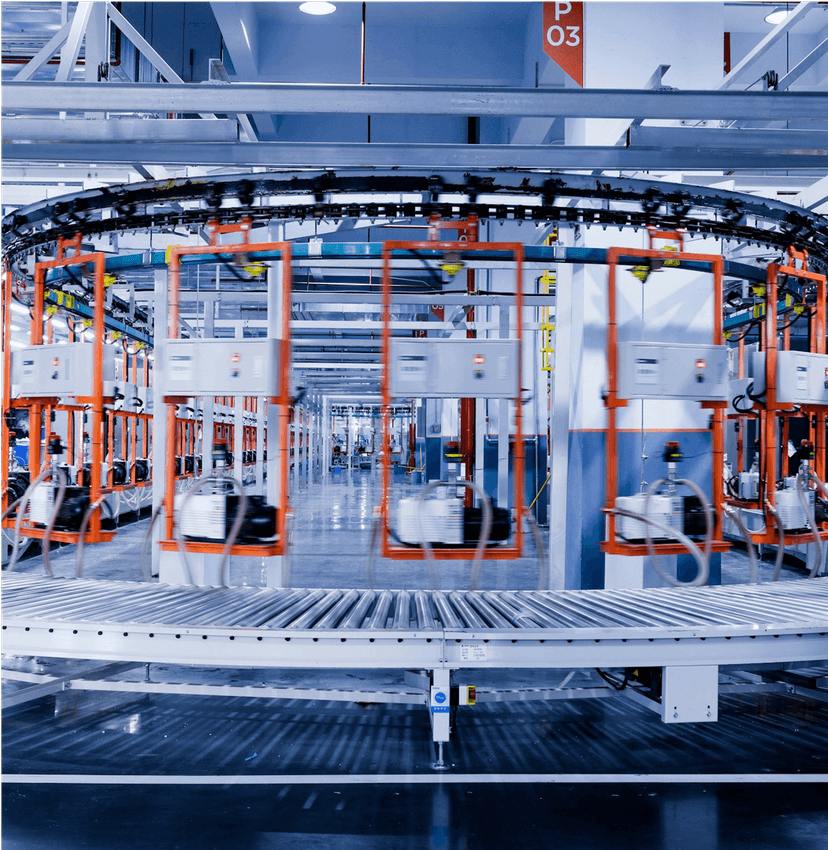

The deployment focused on creating a wireless monitoring network for the existing vacuum pressure gauges without disrupting production:

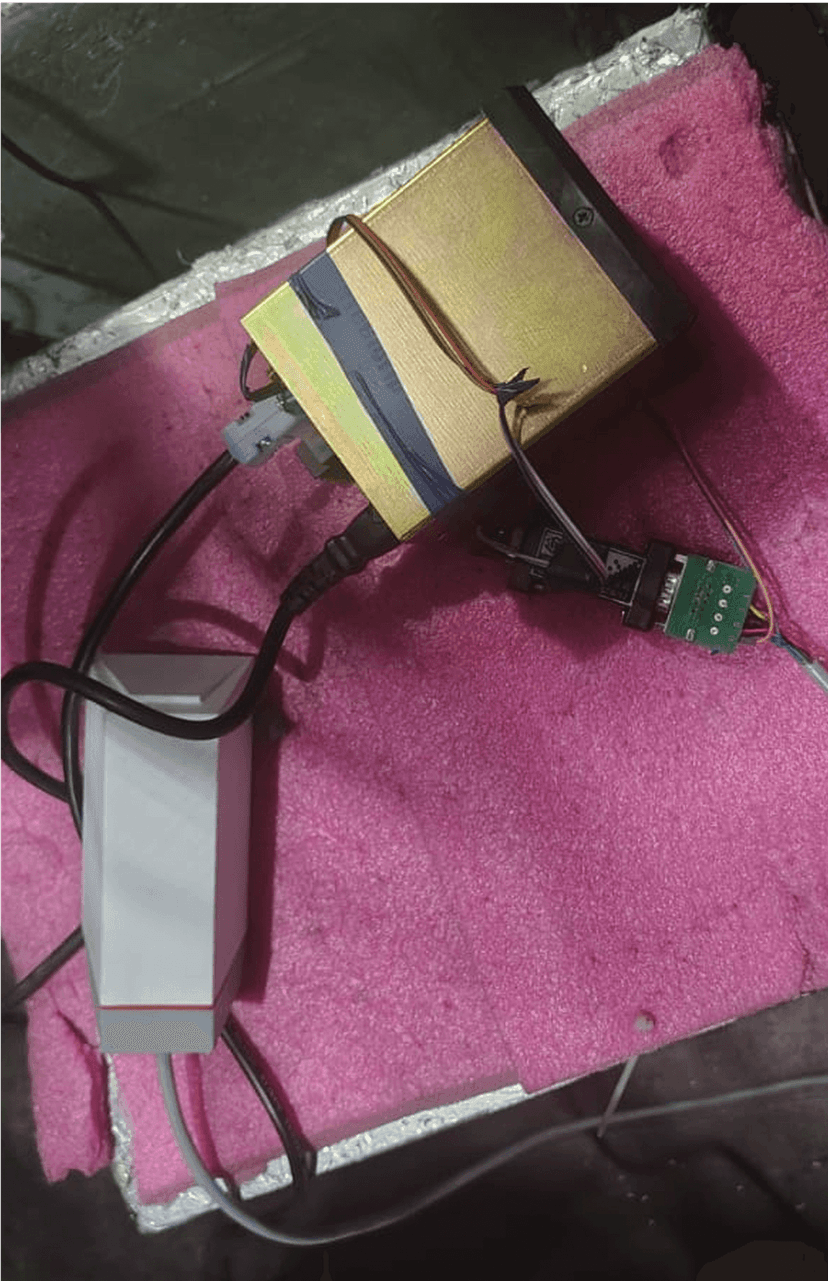

MacSync Series RS485-to-LoRaWAN Data Loggers

Installed on each vacuum pressure gauge to capture readings and transmit them over LoRaWAN..

Industrial LoRaWAN Gateway

Aggregated data from all MacSync loggers and sent it to the SCADA system for real-time visualization.

SCADA System Integration

Data was mapped directly into existing dashboards for trend analysis, alert management, and automated actions..

Local Indicators

Additional indicators are installed in line with the MacSync RS485 to LoRaWAN Datalogger for the visual alerts.

Deployment Challenges: Overcoming Greenhouse Hurdles

RS485 Compatibility

Ensuring all gauges communicated seamlessly with the MacSync LoRaWAN Data Loggers without hardware modifications.

Signal Interference

Metallic structures and machinery on the production floor created wireless signal obstacles, requiring careful placement of loggers and gateways.

Scalability Concerns

The system needed to accommodate future expansion without additional wiring or major infrastructure changes.

Non-Intrusive Installation

The system needed to accommodate future expansion without additional wiring or major infrastructure changes.

Impact: Real-Time Insights, Smarter Decisions 🚀

Centralized Data

All vacuum pressure readings were collected and visualized on SCADA dashboards in real-time.

Faster Response

Stable temperature and humidity control ensured uniform growth and healthier plants across all zones.

Reduced Manual Checks

Continuous monitoring allowed for optimized production and preventive maintenance.

Seamless SCADA Integration

Data flowed directly into existing systems, enabling automated alerts and trend analysis.

Full Regulatory Compliance

Continuous logging of pressure values satisfied audit requirements and ensured traceability.

Validation and Testing: Accuracy and Reliability ✅

Wireless Signal Testing

Checked LoRaWAN connectivity across the production floor, ensuring consistent coverage and low latency.

SCADA Integration Validation

Continuous monitoring simulated different environmental scenarios, ensuring instant alerts and automated responses functioned correctly.

Stress Testing

All devices were subjected to heat, humidity, and dust conditions to verify IP67-rated reliability under greenhouse conditions.

Long-Duration Reliability Test

Ran the network for several days to confirm stable, uninterrupted performance.

Conclusion: Real-Time Vacuum Pressure Monitoring with LoRaWAN

With MacSync RS485-to-LoRaWAN Data Loggers, the refrigeration manufacturer achieved centralized, wireless monitoring of vacuum pressure gauges across production lines.

This deployment transformed siloed vacuum pressure gauges into a connected, intelligent LoRaWAN network, enabling predictive maintenance, optimized production, and actionable insights all while keeping the facility running smoothly.

Read more on the Real-time LoRaWAN monitoring for industrial warehousing