Mining Truck Tracking

In the heart of the mine, trucks are the backbone of operations moving tons of material every day. Yet, without proper monitoring, fleet performance and location visibility are often blind spots, leading to delays, inefficient routes, and unplanned maintenance.

Macnman Technologies stepped in with the MacSync series IoT controllers, connecting seamlessly to existing RS485 sensors already installed on trucks. This allowed mining operators to track each truck’s location, monitor engine and sensor performance, and collect actionable data all in real time.

With low-power, long-range LoRaWAN connectivity, this system works reliably even in the challenging, metallic-heavy environment of mines, turning raw sensor data into actionable insights for operators and managers alike.

The Problem: Blind Spots in Mining Fleet Operations ⛏️

Mining operations rely heavily on trucks for material transport, but lack of visibility and real-time data often causes inefficiencies and operational risks.

Untracked Routes

Without precise location data, trucks can take inefficient paths, wasting fuel and slowing material flow.

Reactive Maintenance

Repairs were performed only after failures occurred, causing unplanned downtime and production delays.

Limited Integration

Existing RS485 sensors were underutilized; the data wasn’t connected to a central monitoring system for actionable insights.

Vehicle Performance

Engine hours, fuel consumption, and mechanical stress were manually logged or guessed, leading to unexpected breakdowns.

Proposed Solution: Real-Time Truck Tracking & Performance Monitoring

To eliminate blind spots in mining fleet operations, Macnman deployed MacSync series IoT controllers on trucks, leveraging existing RS485 sensors. This setup enabled real-time location tracking, performance monitoring, and automated reporting, all without disrupting existing infrastructure.

- 01

IoT Sensors Integration

Installed directly on trucks, the controllers interface seamlessly with existing RS485 sensors, collecting engine, fuel, and operational data.

- 02

Real-Time Location Tracking

GPS integration provides continuous, precise truck location data for route optimization and operational planning.

- 03

Vehicle Performance Monitoring

Monitors engine hours, fuel consumption, speed, and other performance metrics, helping predict maintenance needs and reduce unexpected downtime.

- 04

Automated Data Logging

All sensor and location data is logged in real time to a central dashboard, eliminating manual record-keeping and data gaps.

- 05

Predictive Maintenance Alerts

Intelligent thresholds trigger alerts for preventive maintenance, reducing mechanical failures and costly emergency repairs.

- 06

Dashboard Visualization

Operations teams can view fleet performance, route efficiency, and vehicle health on a single dashboard, enabling data-driven decisions.

LoRaWAN Architecture: Mining Truck IoT Network

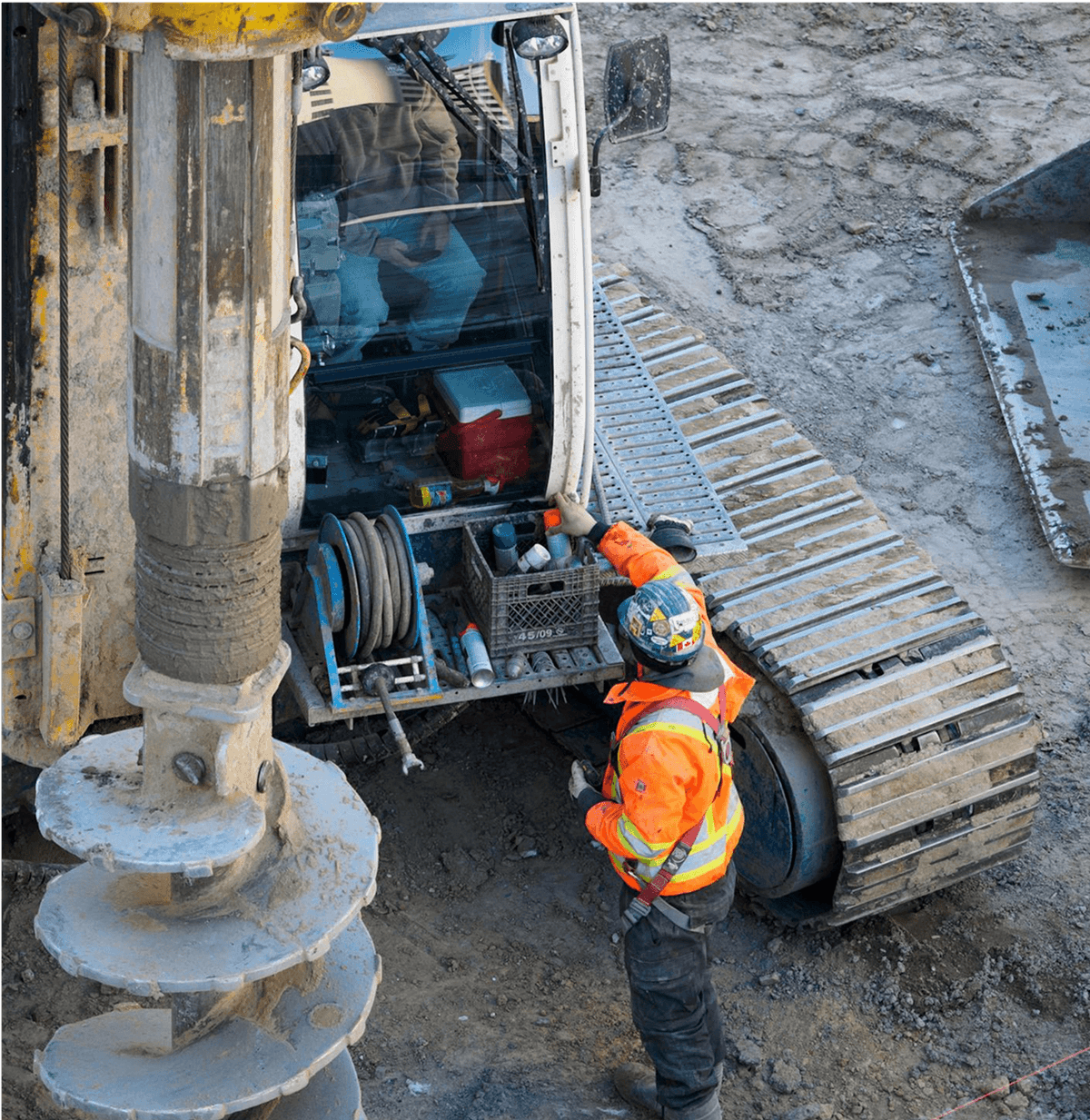

Deployment: Seamless Integration on Mining Trucks

Installing a real-time tracking and performance monitoring system in a busy mining environment required careful planning to minimize downtime and leverage existing infrastructure.

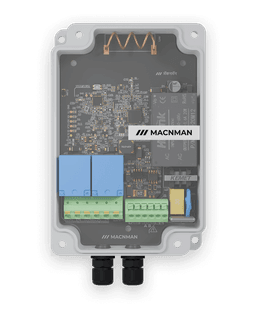

MacSync L-Series

Connected directly to existing RS485 sensors on each truck. Collected engine metrics, fuel consumption, speed, and operational data..

LoRaWAN Gateway

Connects all greenhouse sensors, Enables long-range data transmission, Centralizes data for monitoring.

LoRaWAN Controller

Controls irrigation and actuators Automates environmental adjustments Reduces manual intervention.

GPS Module

Provided precise truck location tracking in open-pit and semi-underground zones.

Deployment Challenges: Navigating Industrial Mining Conditions

Connectivity in Harsh Mining Zones 📡

Placement of LoRaWAN gateways and high-gain antennas was optimized to ensure reliable communication with all trucks.

RS485 Sensor Integration ⚙️

Trucks already had RS485 sensors installed. Configuring MacSync L-Series controllers to collect accurate, real-time data without disrupting existing wiring required precise mapping and calibration.

Andon Light Control Reliability 💡

The MacSet LoRaWAN controller needed to trigger Andon lights based on performance thresholds instantly.

Environmental Stress on Devices 🌦️

Mining trucks operate in high-vibration, dusty, and temperature-extreme conditions. Ruggedized enclosures and secure mounting of all devices.

Impact of Smarter Farming with LoRaWAN

Optimized Routes & Fuel Efficiency

Real-time GPS tracking ensures trucks follow the most efficient paths, reducing fuel consumption and transport delays.

Reduced Downtime ⏱️

Continuous performance monitoring and predictive maintenance alerts minimize unexpected breakdowns, keeping operations smooth and on schedule.

Real-Time Operational Visibility 👀

Operators gain instant insights into truck locations, engine health, and performance metrics — even in underground or semi-open mining zones.

Scalable & Flexible System 🌐

The MacSync LoRaWAN network supports adding more trucks, sensors, or controllers seamlessly as the mining fleet grows.

Data-Driven Decisions 📊

Historical logs and live metrics allow managers to plan maintenance schedules, optimize routes, and improve overall fleet efficiency

Testing & Validation: Ensuring Accuracy & Reliability

LoRaWAN Network Reliability 📡

Checked communication between trucks, gateways, and the central dashboard.

Ensured low-latency, uninterrupted data transmission across the mining site.RS485 Sensor Data Accuracy ⚙️

Verified that engine metrics, fuel consumption, and operational data from existing sensors were accurately captured by MacSync L-Series.

Dashboard Functionality 📊

Verified that real-time data visualization, alerts, and historical logs were accurate and actionable.

Andon Light Response

Validated MacSet LoRaWAN controllers could trigger Andon lights instantly based on performance thresholds.

Conclusion: Turning Data into Decisions Underground

The deployment of MacSync W-Series LoRaWAN Controllers and Macnman Gateways transformed traditional mining fleet management into a data-driven operation.

By integrating seamlessly with existing RS485 sensors, our solution enabled real-time tracking of truck performance, precise location mapping, and automated Andon alerts all without modifying the truck’s native systems.

The result?

Improved fleet utilization, reduced downtime, and smarter maintenance scheduling — ensuring that every truck in the mine contributes its maximum efficiency.

This case stands as a testament to how Macnman’s industrial IoT innovation bridges rugged hardware with intelligent connectivity, helping industries see beneath the surface and act before issues arise.

Next story: Smart Drainage Automation with Ultrasonic Sensors