PLC-to-PLC Communication with Long-Range LoRa

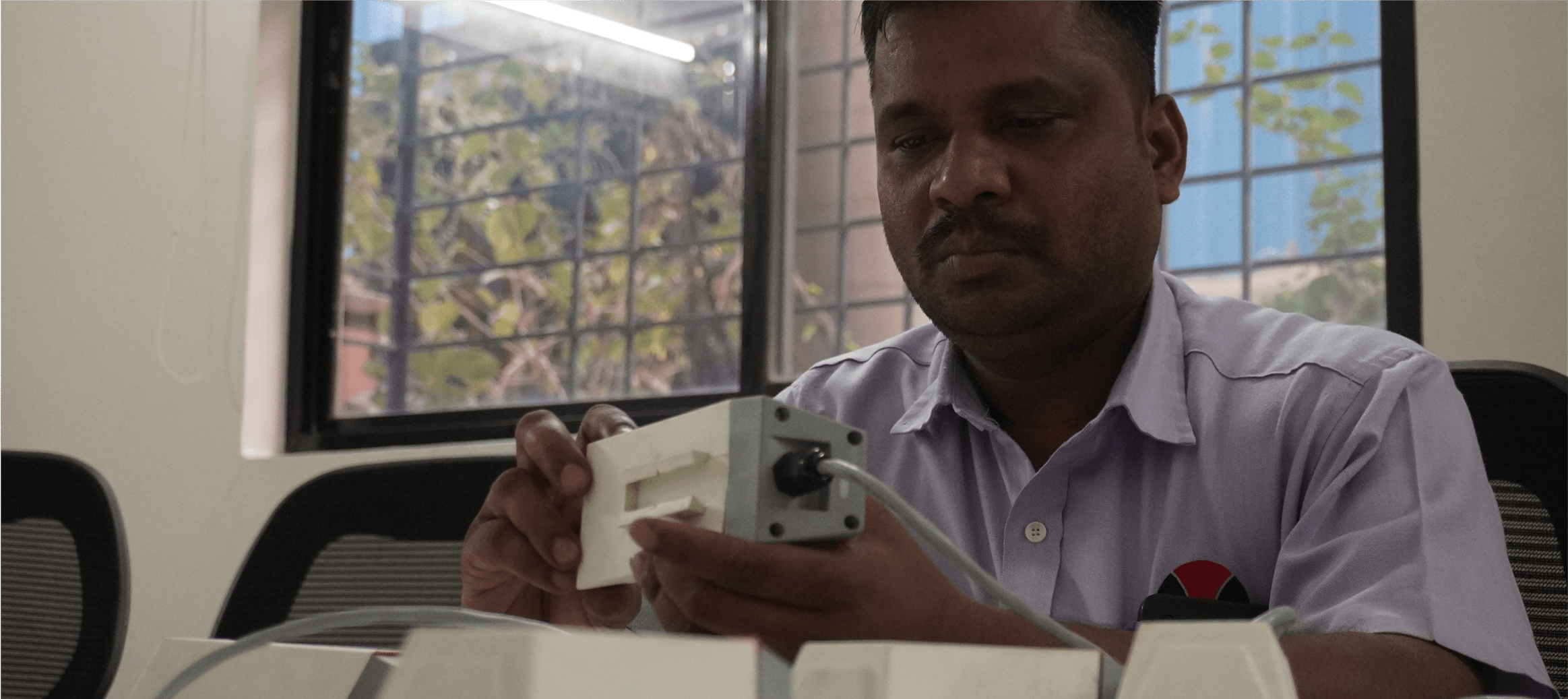

SVR Robotics faced challenges in automating processes across two PLCs separated by 2 km in an industrial setup. Existing systems could not communicate reliably, causing delays and inefficiencies in valve and controller operations

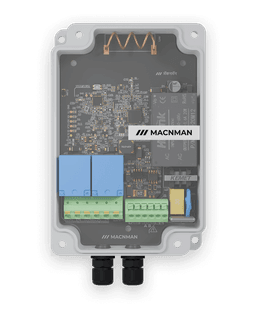

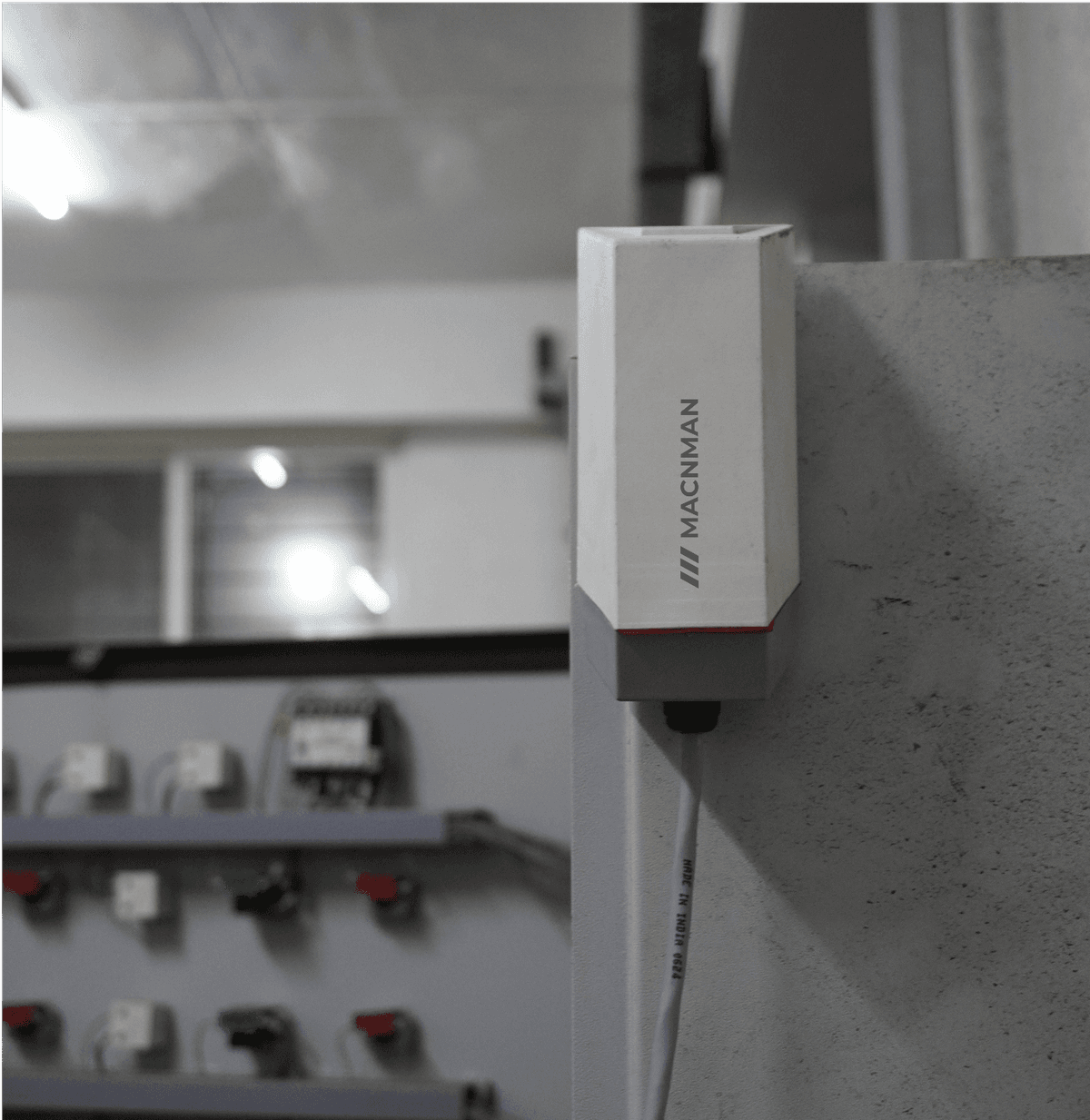

This is where Macnman Technologies stepped in, bringing the MacSync and MacSet system into action a seamless LoRa-based communication link that made remote automation possible even in signal-challenged industrial zones.

Problem: Inefficient PLC Communication in Industrial Automation

SVR Robotics faced significant challenges in automating industrial processes across two PLCs separated by 2 km. Without a reliable communication link, operations were slow, error-prone, and resource-intensive.

Long-Range Data Gap

PLCs could not exchange real-time process data across 2 km of industrial terrain.

Manual Intervention Bottlenecks

Operators had to manually trigger valves and controllers, slowing operations.

Lack of Infrastructure

Wired or internet connections were impractical for long-distance industrial automation.

Increased Risk

Absence of automated data exchange introduced safety and reliability concerns.

Proposed Solution: Long-Range Industrial PLC Communication via LoRa

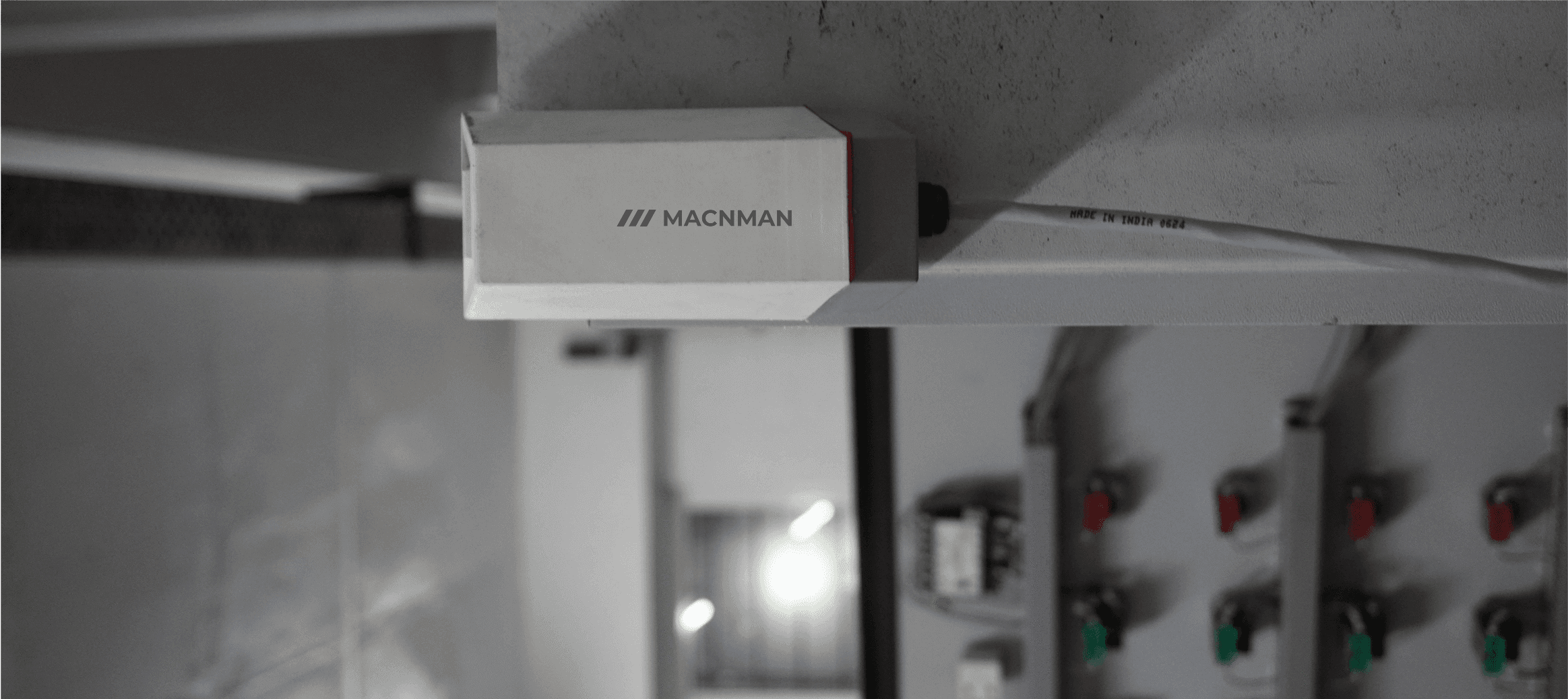

To overcome industrial automation challenges over 2 km, SVR Robotics leveraged MacSync and MacSet LoRaWAN controllers to create a reliable PLC-to-PLC communication link, enabling real-time data exchange and automated control without changing existing infrastructure.

- 01

MacSync Node at Source PLC

Captures critical PLC process data and transmits it via long-range LoRa communication.

- 02

MacSet Controller at Target PLC

Acts as a Modbus slave to the secondary PLC, ensuring seamless industrial automation.

- 03

Automated Operations

Enables the target PLC to operate valves and controllers automatically, reducing manual interventions.

- 04

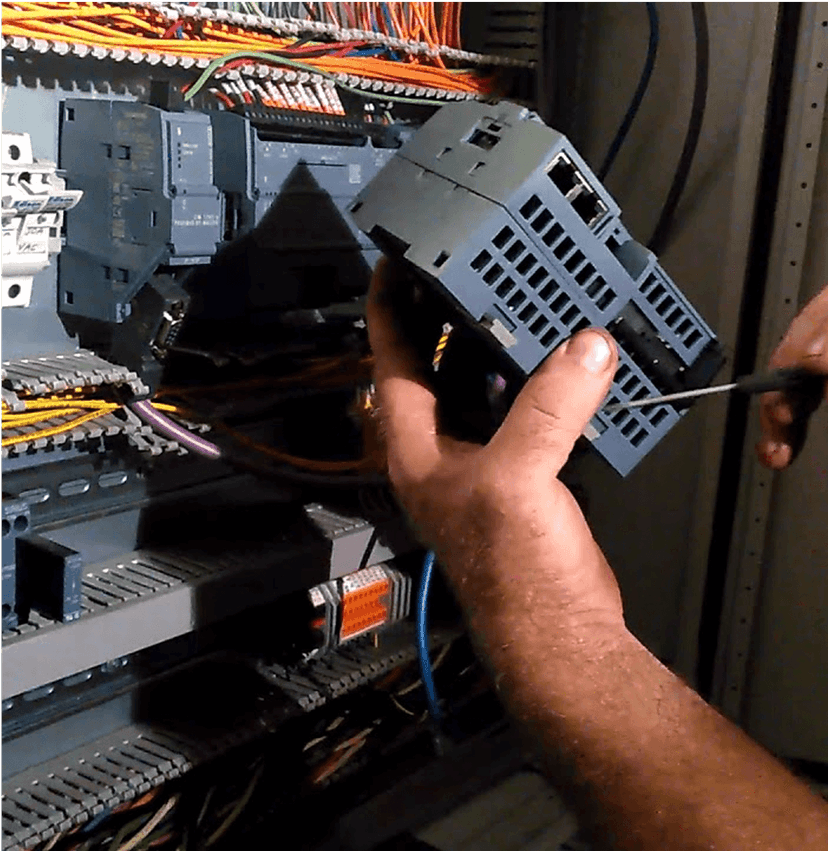

Plug-and-Play Industrial Integration

Requires no modifications to existing PLCs, valves, or industrial control systems.

- 05

Reliable 2 km LoRa Connectivity

Ensures low-latency, high-accuracy communication in industrial environments.

- 06

Enhanced Operational Efficiency

Improves process automation, resource utilization, and operational safety.

IoT Architecture for Smart Air Quality Monitoring

Deployment : Long-Range LoRa Communication Between MacSync & MacSet

The system architecture was designed to enable reliable, long-distance communication between remote water level sensors and motor control units using LoRa technology.

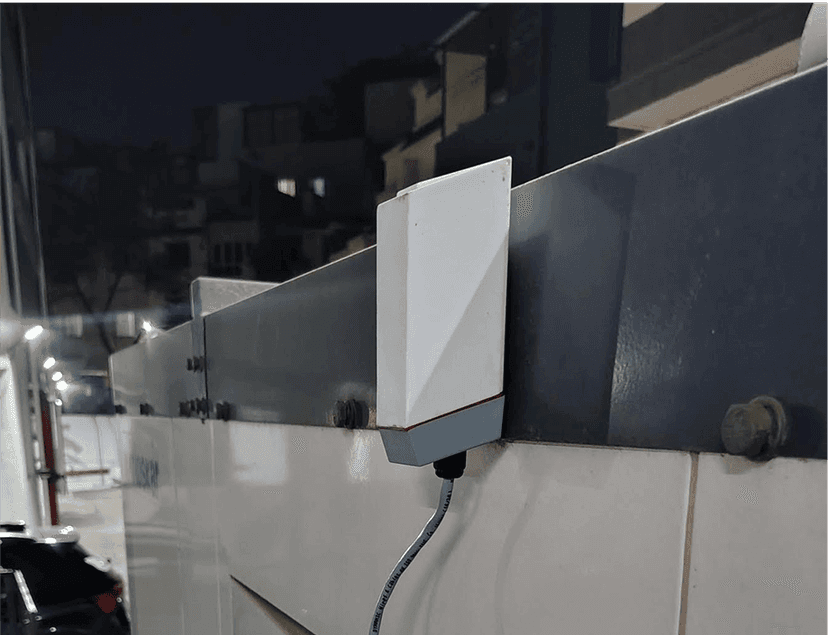

MacSync LoRaWAN Node

Installed at the source PLC, capturing real-time process data and transmitting it via long-range LoRa P2P communication.

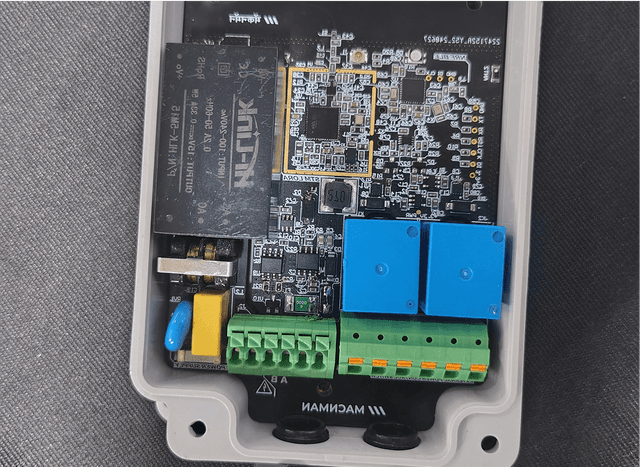

MacSet Controller

Deployed near the valve and motor control system to receive LoRa data from MacSync and communicate with the PLC through RS485 Modbus RTU.

SCADA Compatibility

The system architecture allows future integration with SCADA systems, enabling centralized monitoring and advanced data visualization.

PLC Logic Integration

The PLC used the incoming data to decide when to start or stop the motor, automating the entire water flow control process.

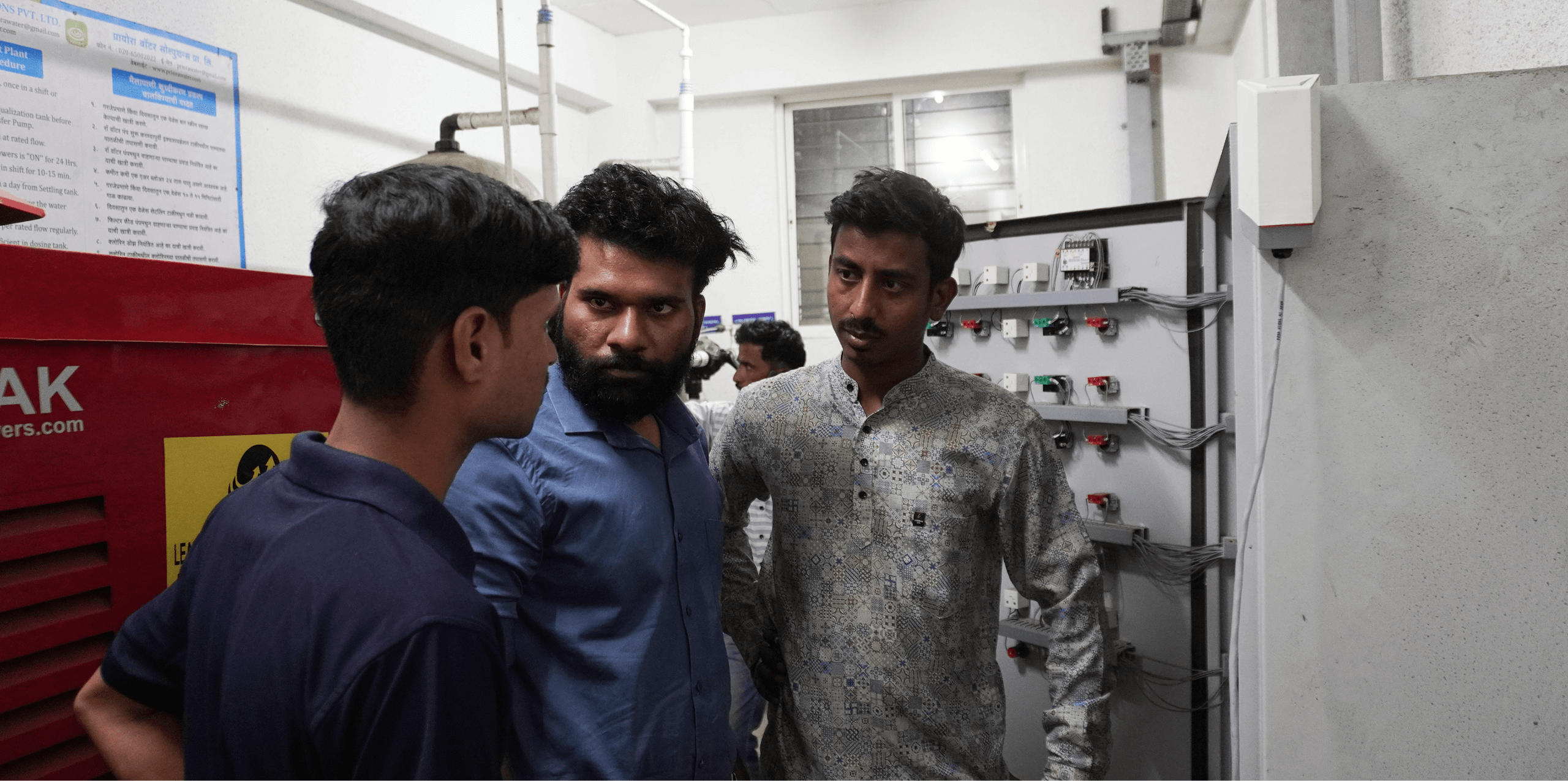

Deployment Challenges: Ensuring Reliable Long-Range PLC Communication

Long-Range LoRa Connectivity

Maintaining stable LoRa communication over 2 km in an industrial environment with potential interference.

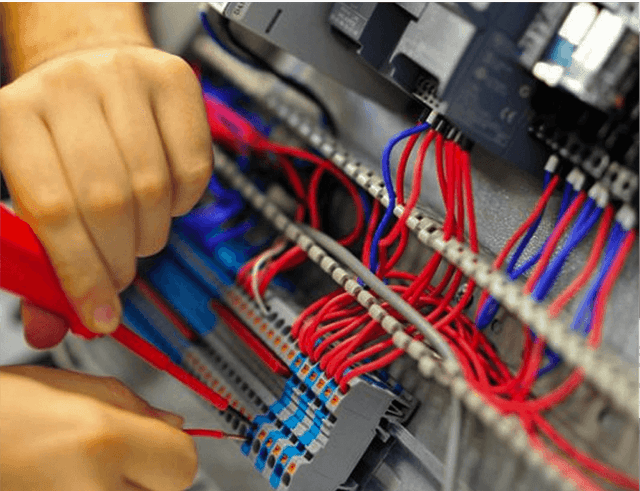

Seamless PLC Integration

Integrating MacSync and MacSet controllers with existing PLCs without modifying control logic.

Industrial Noise & Signal Interference

Overcoming electrical noise, metal obstructions, and machinery interference for accurate data transfer.

Scalable Industrial Network

Designing for future SCADA integration and additional PLC expansions without extra infrastructure

Impact: Enhanced Industrial Automation with LoRaWAN PLC Integration

Real-Time Automated Control

Valves and controllers now operate automatically and accurately, reducing manual interventions.

Reduced Human Error

Automation minimizes manual mistakes, enhancing safety and reliability.

Cost Savings on Infrastructure

Eliminates the need for long-distance cabling or internet lines, reducing installation and maintenance costs.

Future-Ready Scalability

The network supports additional PLCs and SCADA integration, future-proofing industrial automation.

Testing & Validation: Ensuring Reliable Long-Range PLC Automation

End-to-End Data Verification

Confirmed accurate transmission of PLC data over 2 km without loss.

Latency & Response Testing

Ensured low-latency communication for immediate valve and controller operation.

PLC Integration Accuracy

Verified MacSync and MacSet nodes accurately communicated with PLCs as Modbus slave/master.

Reliability Over Continuous Operation

Long-duration tests confirmed stable, automated operations under real industrial conditions.

Conclusion: Transforming Industrial Automation with Long-Range LoRaWAN

By deploying MacSync and MacSet LoRaWAN controllers, SVR Robotics successfully enabled seamless PLC-to-PLC communication across 2 km, automating valve and controller operations without altering existing infrastructure.

- Enhanced Automation • Industrial processes now operate automatically and efficiently, reducing manual intervention.

- Reliable Long-Range Connectivity • Stable 2 km LoRa P2P link ensures real-time, low-latency data exchange.

- Operational Efficiency & Cost Savings • Eliminated need for long-distance cabling and reduced manual errors, improving productivity.

- Future-Ready Industrial Network • Architecture supports SCADA integration and additional PLC expansion, enabling scalable industrial automation.

This solution demonstrates how LoRaWAN technology can revolutionize long-distance industrial automation, delivering efficiency, reliability, and cost savings for complex operations.

Unlock the next real-world IoT deployment for Your Industry