Smart Battery Health Monitoring

At Luminous, battery testing isn’t just about performance, it’s about precision and safety. Their testing rigs, running multiple batteries in parallel, needed continuous monitoring of temperature, current, and voltage to prevent overheating, short circuits, or electrical faults.

However, the existing setup relied heavily on manual checks and local meters, offering limited real-time insights. Any small deviation during charge or discharge cycles could go unnoticed until it was too late risking both equipment and personnel safety.

That’s where Macnman’s Wi-Fi-enabled IoT monitoring and control system stepped in.

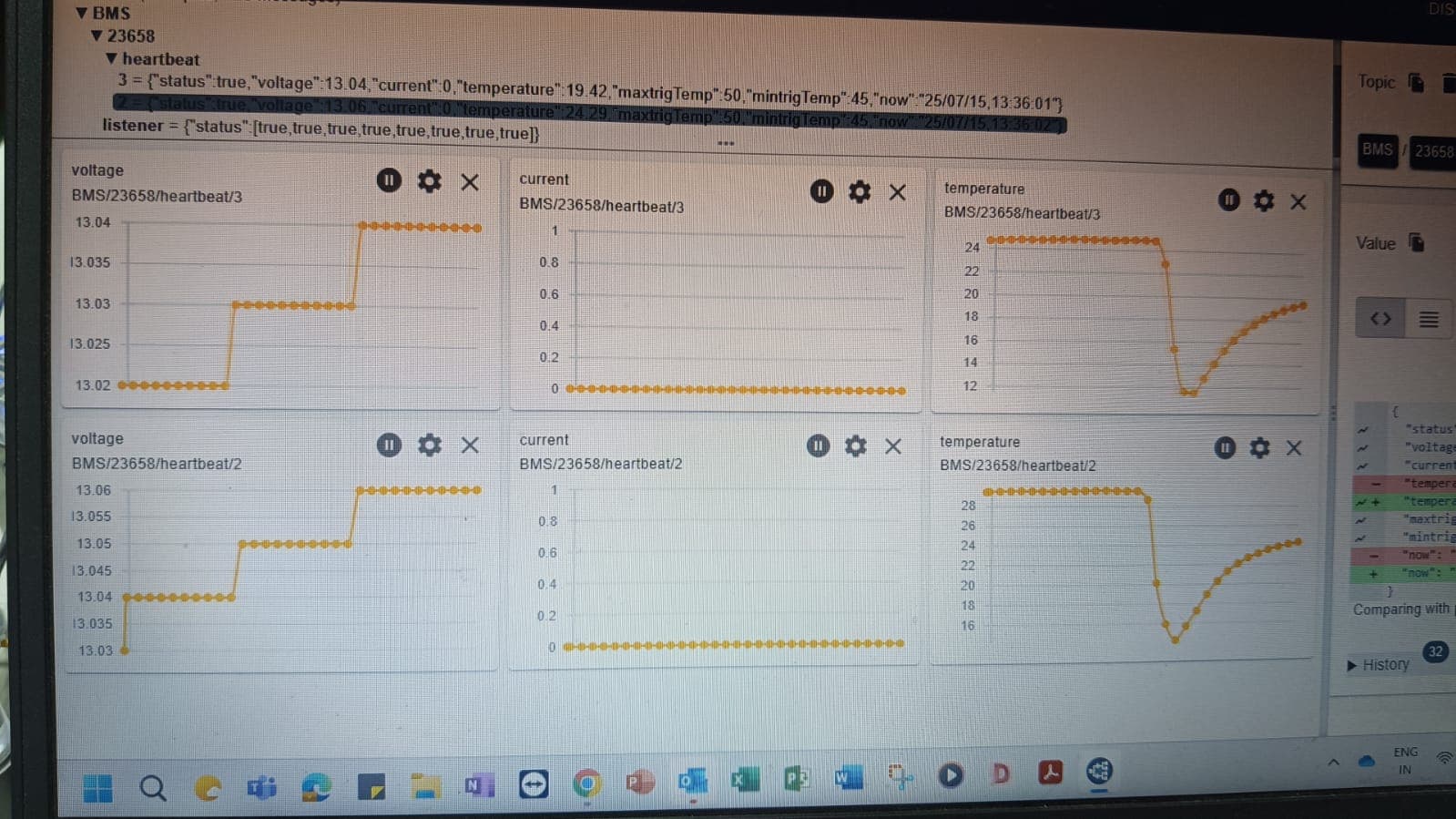

By integrating BMS Type 2 , Wi-Fi Series Nodes directly into the test rigs, every parameter, temperature, voltage, and current, became visible in real time on the SCADA dashboard. The system also introduced automated safety controls, instantly cutting off power when thresholds were breached.

The Challenge: Manual Monitoring, High Risk ⚠️

Even with advanced test benches, Luminous faced critical challenges in ensuring safe and consistent testing of their high-capacity batteries. The system’s manual nature left room for error, delay, and potential hazards.

Delayed Detection

Temperature and voltage deviations were often spotted too late during manual checks.

Overheating Risks

Without automated alerts or shutdown, high current surges could lead to overheating or even fire hazards.

Lack of Automated Safety Control

In critical situations, technicians had to intervene physically, increasing risk exposure.

Safety Risks

Delayed responses during belt jams or overloads put both equipment and personnel at risk.

Proposed Solution: Intelligent Wi-Fi Monitoring and Control System

To overcome the safety and visibility challenges in Luminous’s testing facility, Macnman Technologies deployed a Wi-Fi-based smart monitoring and control network built on the MacSync Wi-Fi Series. The goal was not just to observe — but to act intelligently when parameters crossed critical thresholds.

- 01

Wireless Real-Time Monitoring

Continuous tracking of temperature, voltage, and current across every test rig using high-accuracy digital sensors.

- 02

Smart Threshold-Based Control

When any reading exceeded the predefined safety limits, the system automatically triggered relays to cut power and prevent damage.

- 03

Seamless SCADA Integration

Data from each BMS Units was transmitted via Wi-Fi to the central SCADA system for real-time visualization and historical trend analysis.

- 04

Local Control Panel Feedback

A dedicated panel displayed live readings and allowed manual overrides when needed giving engineers on-ground control confidence.

- 05

Event Logging and Alerts

Every anomaly, shutdown, or recovery event was logged and pushed as alerts to supervisors, ensuring instant awareness and traceability.

- 06

Scalable and Modular Setup

The architecture was designed to expand easily — accommodating more test rigs or adding extra sensors without rewiring.

System Architecture: From Sensors to Smart Decisions ⚙️

Deployment: Smart Integration Across Every Test Rig 🔧

The deployment at Luminous’s facility focused on creating a seamless and modular Wi-Fi network that connected every battery testing station — without disrupting existing infrastructure. Each component was carefully chosen to ensure precision, reliability, and safety automation.

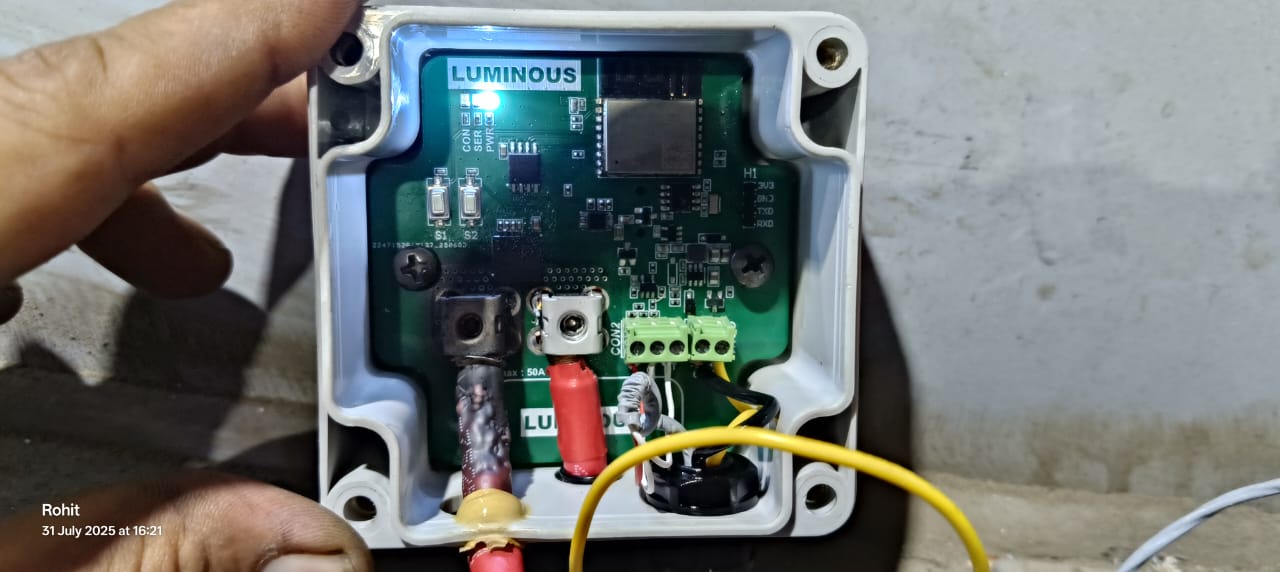

BMS Wi-Fi Series Nodes

Installed on every test rig to capture temperature, voltage, and current in real time.

These nodes acted as the core IoT data collectors, transmitting all readings wirelessly to the SCADA system.

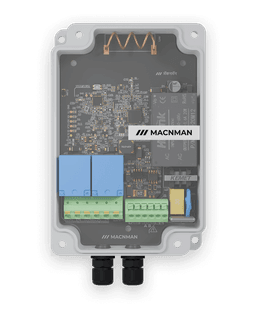

MacSet - Wi-Fi Controller

Connected to the rig’s relay control circuits, this unit automatically shut down charging or discharging when any sensor exceeded predefined safety thresholds — ensuring zero delay in response.

Industrial Access Points

Provided stable Wi-Fi coverage across the test area, creating a secure and high-throughput communication backbone for uninterrupted data transmission.

Central SCADA Interface

Integrated with Macnman's BMS's cloud-ready protocol to visualize live sensor data, trigger alarms, and maintain historical records for analysis and compliance.

Deployment Challenges: Power, Precision, and Protection ⚡

Electromagnetic Interference (EMI)

High-current discharge setups generated significant EMI, disrupting sensor accuracy and Wi-Fi communication. We mitigated this by using shielded cables, isolated sensor inputs, and optimized grounding for each node.

Network Congestion & Wi-Fi Stability

Dozens of rigs operated simultaneously, generating continuous data. To avoid data loss or latency, we used dedicated SSIDs and QoS prioritization, ensuring real-time updates to the SCADA system.

Power Supply Consistency

Rugged IP67 enclosures and vibration-resistant mounting kept the nodes and controllers operational.

Calibration & Threshold Tuning

Each battery model required slightly different safety thresholds. Our team fine-tuned temperature and voltage cutoffs through iterative testing to ensure accurate, model-specific control.

Impact: Smarter Testing, Safer Operations 🚀

Real-Time Safety Assurance

Instant response to abnormal temperature or voltage conditions drastically reduced risks of overheating, short circuits, and equipment failure.

360° Visibility of Every Test Rig

Operators in the control room, 18 km away, can start, stop, and monitor each checkpoint without traveling into the jungle.

Reduced Downtime

Automated fault detection and event logging allowed preventive maintenance before failures occurred, increasing rig availability.

Improved Data Accuracy

Digital sensors and continuous logging eliminated human error, ensuring precise records for audits and quality analysis.

Validation and Testing: From Prototype to Proven Performance ✅

Bench-Level Calibration Tests

All temperature, voltage, and current sensors were calibrated against certified instruments. The system achieved >98.5% measurement accuracy, meeting industrial standards for precision.

Load and Response Testing

Simulated overcharge and high-discharge conditions were introduced intentionally. The MacSet Controller successfully triggered power cutoffs in under 200 milliseconds, proving its responsiveness to threshold breaches.

Network Performance Validation

Continuous Wi-Fi data transmission was tested under simultaneous multi-rig operation. The network maintained real-time updates with zero packet loss for over 72 hours of continuous testing.

Safety Redundancy Check

Validated real-time data sync between LoRaWAN network and the control room SCADA system.

Conclusion: Precision, Protection, and Performance Redefined

The collaboration between Luminous and Macnman Technologies turned a traditionally manual, high-risk testing process into a smart, self-regulating ecosystem. With real-time monitoring, intelligent cutoffs, and seamless SCADA integration, safety became proactive rather than reactive.

What began as a need for accurate readings evolved into a connected testing platform — one that not only monitors every detail but also acts instantly to protect people, infrastructure, and equipment.

Luminous now runs its testing floors with confidence, clarity, and control — powered by data, driven by safety, and designed for the future.

How we connected a 22 km conveyor line through the jungle with LoRaWAN automation.