Check How UWB Cut Waiter Response Time

A fast-moving Quick Service Hotel was losing guests—not because of food quality, but because of slow service.

During peak hours, waiters responded late, guest requests piled up, and large sections of the dining area were left unattended.

Waiters unknowingly clustered in low-demand corners, while high-demand tables had no one nearby.

This created long idle pockets, delayed order pick-ups, and a clear drop in service quality

Without real-time waiter tracking, managers had no visibility into:

- Where each waiter actually was

- Which zones were left unattended

- Who was idle during critical service windows

The Problem: Slow Response & Idle Waiters

Ensuring accurate and real-time positions help to avoid delays

Slow Guest Response Time

Waiters were often positioned far from active tables, causing late order pickup and delayed service during peak hours.

Idle Pockets During Busy Periods

Large sections of the floor had waiters standing idle, while high-demand zones were left unattended

No Real-Time Visibility

Managers couldn’t see where waiters were on the floor, making it hard to assign tasks instantly

Unbalanced Workload Across Waiters

Some waiters handled multiple tables back-to-back while others had almost none, leading to service delays

The Solution: UWB Personal Tracking for Faster, Smarter Waiter Movement

Proposed Solution: A LoRaWAN-based weather station with multi-sensor integration, real-time monitoring, and automated alerts for industrial environments.

- 01

UWB Personal Trackers for Every Waiter

Managers could instantly see who is free, who is busy, and who is closest to a guest request.

- 02

Instant Visibility for Supervisors

Managers could instantly see who is free, who is busy, and who is closest to a guest request.

- 03

Automatic Idle Zone Detection

The system highlighted idle pockets so staff could be redirected during peak hours.

- 04

Zone Coverage Monitoring

Ensured no table or section was left unattended.

- 05

Real-Time Heatmaps for Shift Optimization

Showed where waiters spent time, helping fix slow-response zones quickly.

- 06

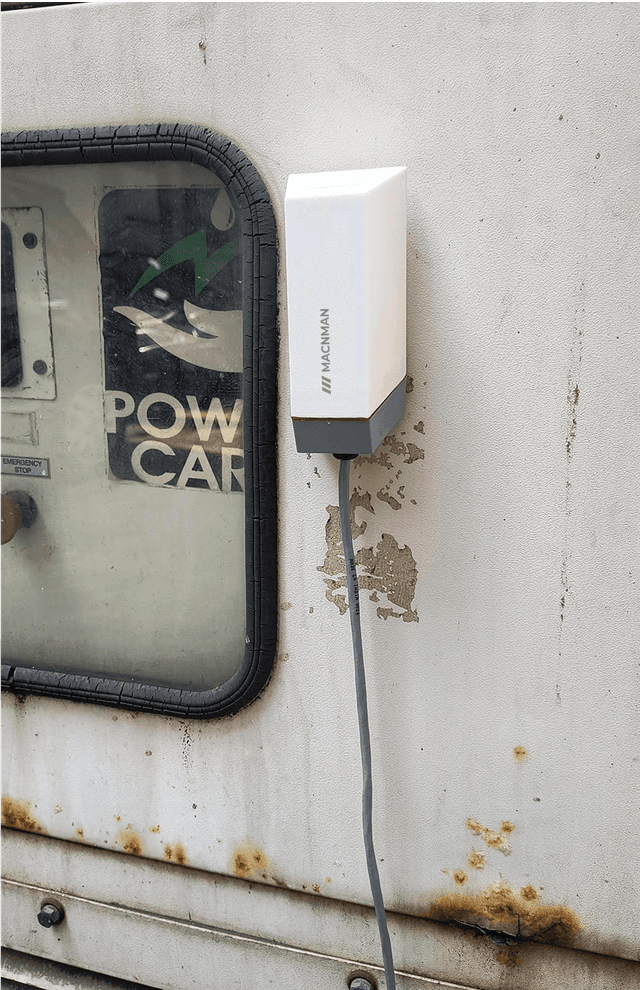

Reliable Power & Enclosure

IP67-rated, solar-assisted setup ensures continuous operation in harsh conditions.

System Architecture: How the Hotel Floor Was Digitized for Real-Time Staff Flow

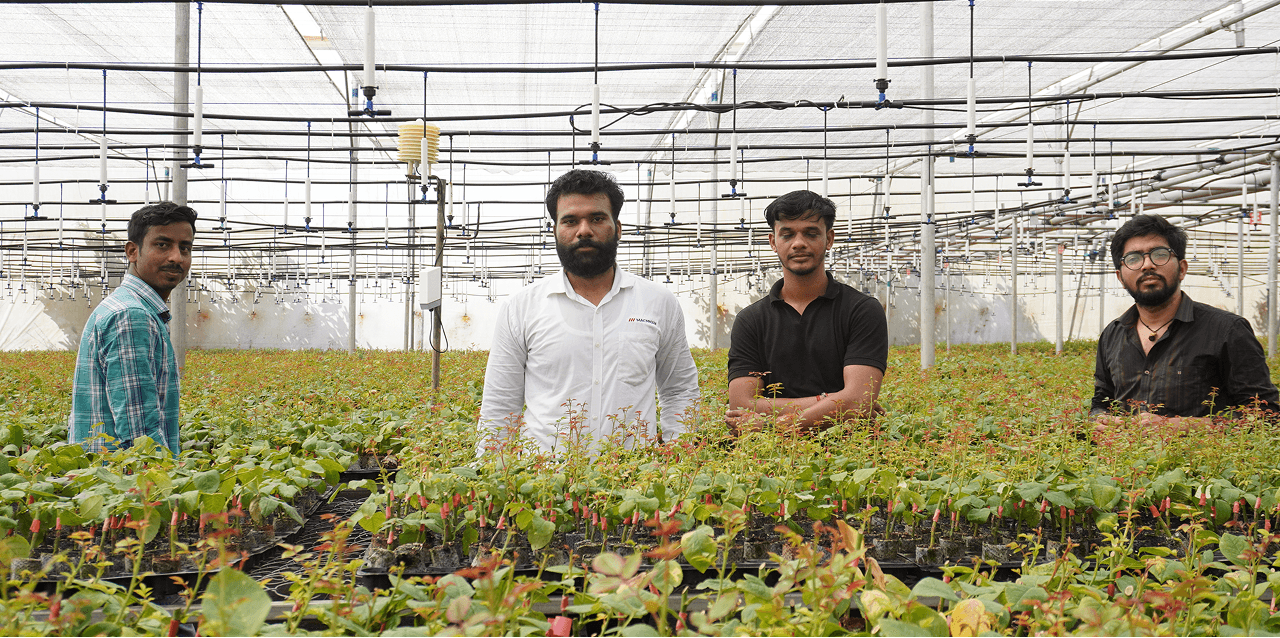

Deployment: Turning the Restaurant Floor Into a Live Staff Monitoring Zone

Deployment of Industrial Weather Sensors: Strategic placement of LoRaWAN weather sensors across the industrial site, connected to gateways and the central dashboard for seamless data collection and monitoring.

UWB Anchors

UWB anchors only where service flow mattered most—table clusters, dish pickup counters, guest entry lanes, and busy junction.

Wearable UWB Badges

Waiters received their UWB badges at sign-in, clipped to their uniform, enabling automatic tracking the moment their shift began.

Central Monitoring Dashboard

A compact processing hub was installed at the main service station to deliver real-time staff updates.

Actual Seating Layout

Managers could instantly see which tables were underserved or overstaffed.

Overcoming Industrial Weather Monitoring Challenges

Overcoming Urban Signal Barriers

Ensuring stable LoRaWAN connectivity across dense city infrastructure for reliable weather data.

Weatherproofing for Reliable Data

Protecting sensors from rain, dust, and extreme temperatures to maintain uninterrupted monitoring.

Sensor Accuracy & Calibration

Sensors calibration was needed to ensure real-time accuracy for temperature, humidity, and rainfall data.

Weatherproofing Protection

Continuous exposure to dust and moisture required rugged enclosures for long-term reliability.

Validation: How We Ensure Industrial Weather Station Data Accuracy

Data Accuracy and Benchmarking

Before deployment, every sensor was individually calibrated in a controlled lab environment against a certified reference instrument

Co-Location Benchmarking

In the field, one of our LoRaWAN nodes was co-located next to a high-end, traditional wired meteorological station used by the local authority.

Network Reliability and Operational Metrics

The long-term value of an industrial IoT weather station hinges on its consistent, autonomous operation

Reduced Field Maintenance

The static (non-moving part) design of critical sensors, such as wind speed/direction, has been validated to eliminate the need for yearly mechanical calibration

Impact of Industrial Weather Station for Smart Factories & Production Efficiency

95% Reduction in Maintenance Costs

LoRaWAN's low power consumption allows stations to run autonomously for up to 5 years on a single battery, eliminating frequent service trips.

Real-Time Microclimate Hazard Alerts

Instant, location-specific data on wind and precipitation drives immediate action, preventing costly operational downtime and ensuring site safety compliance.

60% Faster Critical Data Latency

Data-driven decisions improve traffic, energy, and public services efficiency.

Seamless SCADA/IoT Integration

Standardized APIs allow for plug-and-play integration with existing SCADA, analytics, and data management platforms in less than 72 hours.

Conclusion: Transforming Industrial Operations with LoRaWAN Weather Monitoring

The implementation of the industrial weather station based on LoRaWAN has fundamentally reshaped our client's approach to environmental risk management and operational efficiency. This solution successfully transcends the limitations of legacy monitoring systems by delivering an unparalleled combination of performance, cost savings, and data quality.

Ready to Transform Your Industry with IoT?