Floriculture Cold Storage Monitoring with Temperature, Humidity & Door Status Sensors

In floriculture, cold storage is not just a facility it is the most critical step in protecting flower freshness, appearance, and shelf life before dispatch.

Even a small temperature drift, humidity imbalance, or frequent door opening can reduce quality silently and lead to product rejection at the next stage of the supply chain.

To maintain stable cold room conditions and avoid reliance on manual checks, this customer implemented a complete floriculture cold storage monitoring system using temperature monitoring, humidity monitoring, and door status tracking. The goal was simple: ensure every batch of flowers stays within the right environmental range, with clear visibility of conditions throughout the day and night.

This case study explains how continuous monitoring helped improve consistency, reduce operational risk, and maintain high-quality storage conditions for high-value floriculture inventory.

Problems Faced in Floriculture Cold Storage

Floriculture cold storage is not like storing packaged goods.

Flowers are living products they keep reacting to temperature and humidity even after harvest.

So the problem is not “keeping the cold room ON.”

The problem is keeping it stable while real work is happening.

And that instability is exactly where the financial loss starts.

Imprecise Control Loop

The legacy setup relied on basic thermostats and wide-tolerance hygrometers, making it difficult to consistently maintain 0°C to 4°C and 90% RH (±2%).

Destructive Humidity Fluctuations

Even short humidity drops caused flowers to dehydrate, directly reducing freshness and vase life.

High Shrinkage & Financial Loss

This combination of poor accuracy and slow correction resulted in repeated product quality loss, shrinkage, and avoidable revenue impact.

Data Lag & Blind Spots

Limited sensor coverage missed temperature and humidity pockets inside the room, forcing teams into reactive manual adjustments that were slow and often ineffective.

The Solution: LoRaWAN-Based IoT for Automated Cold Storage Monitoring & Control

To eliminate temperature and humidity drift in the floriculture cold storage, we deployed a LoRaWAN-based IoT monitoring system designed for continuous environmental tracking and faster corrective action.

The solution combines temperature monitoring, humidity monitoring, and door status sensing to capture the real conditions inside the cold room including the fluctuations caused by frequent door activity and airflow imbalance.

- 01

Real-time Humidity Monitoring

LoRaWAN sensors continuously track humidity levels to maintain ideal storage conditions.

- 02

Temperature Control Automation

Automated alerts and control mechanisms adjust cooling systems to keep temperature stable.

- 03

Humidifier Motor Management

IoT-enabled control of humidifier motors to prevent over- or under-humidification.

- 04

Remote Data Access

Real-time monitoring and control via cloud dashboard for managers and operators.

- 05

Preventive Alerts

Instant notifications for deviations from set thresholds, reducing flower spoilage risk

- 06

Reliable Power & Enclosure

IP67-rated, solar-assisted setup ensures continuous operation in harsh conditions.

End-to-End LoRaWAN System Architecture for Cold Storage

Cold Storage Deployment Diagram: Sensor Placement & Coverage

Deployment was planned with one simple goal: capture the real cold storage conditions where flowers are actually stored, not just where it’s convenient to mount a sensor.

We placed the temperature and humidity sensors inside the cold room at practical monitoring points so they reflect the true environment experienced by the product during storage and dispatch cycles.

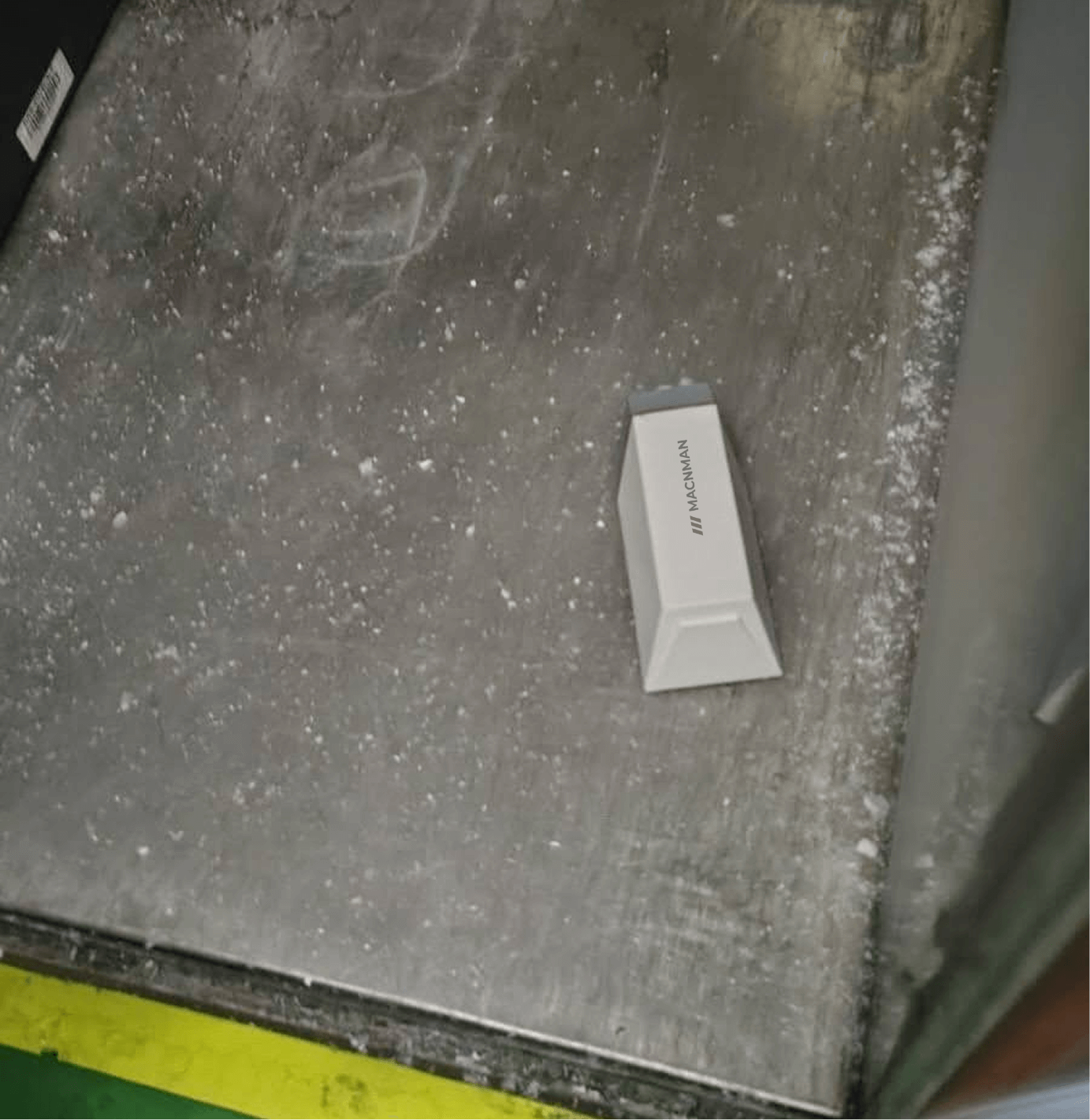

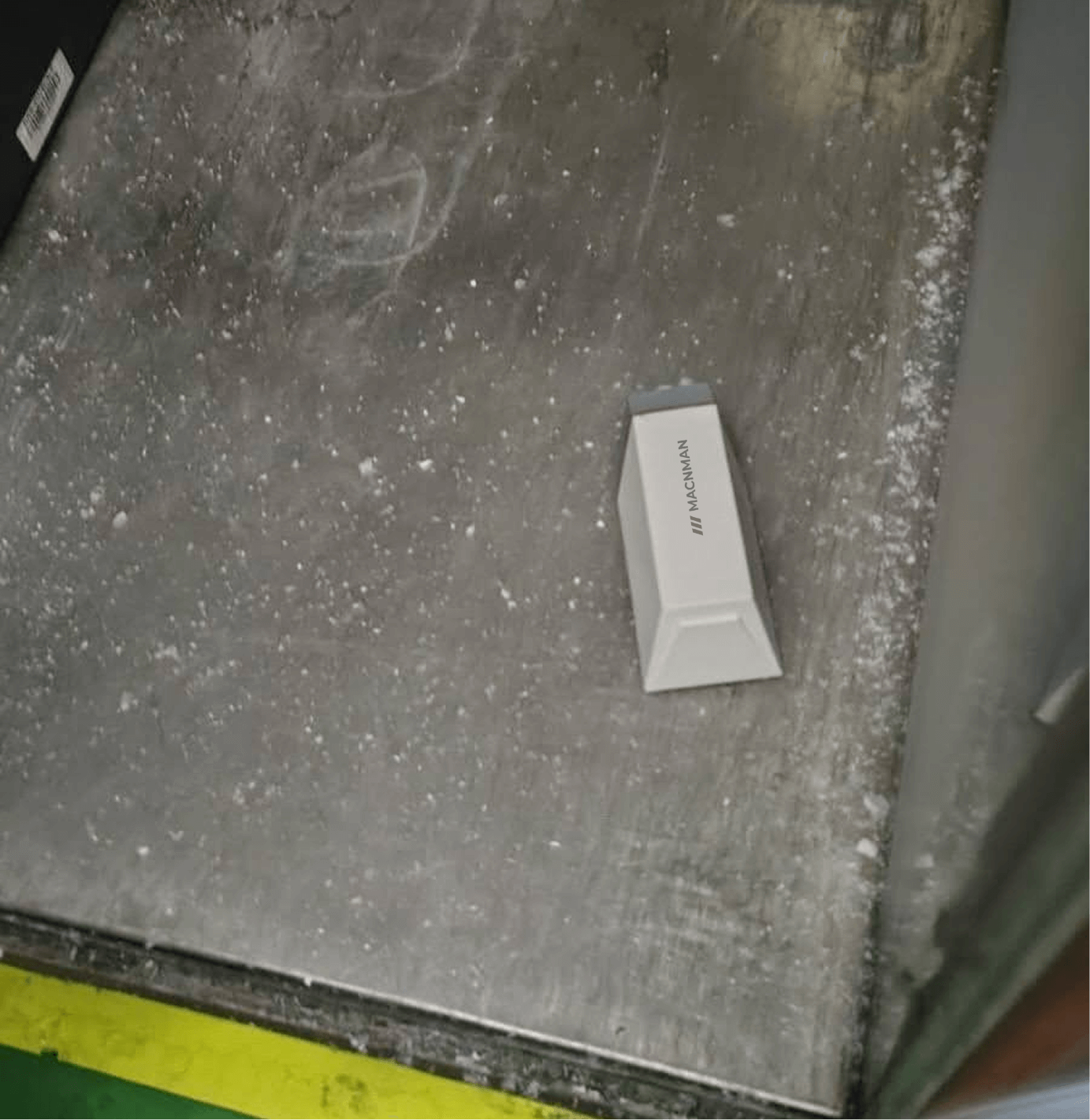

MacSync Temperature Humidity Sensors

Installed inside cold rooms for precise environmental tracking.

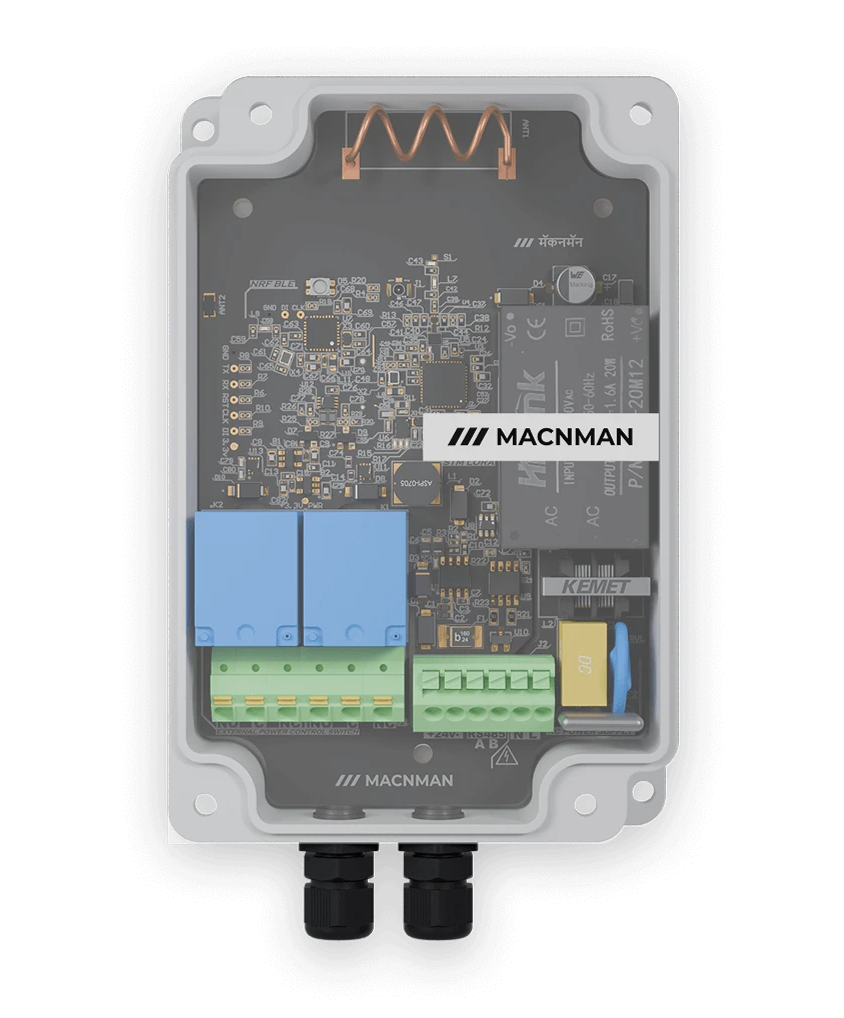

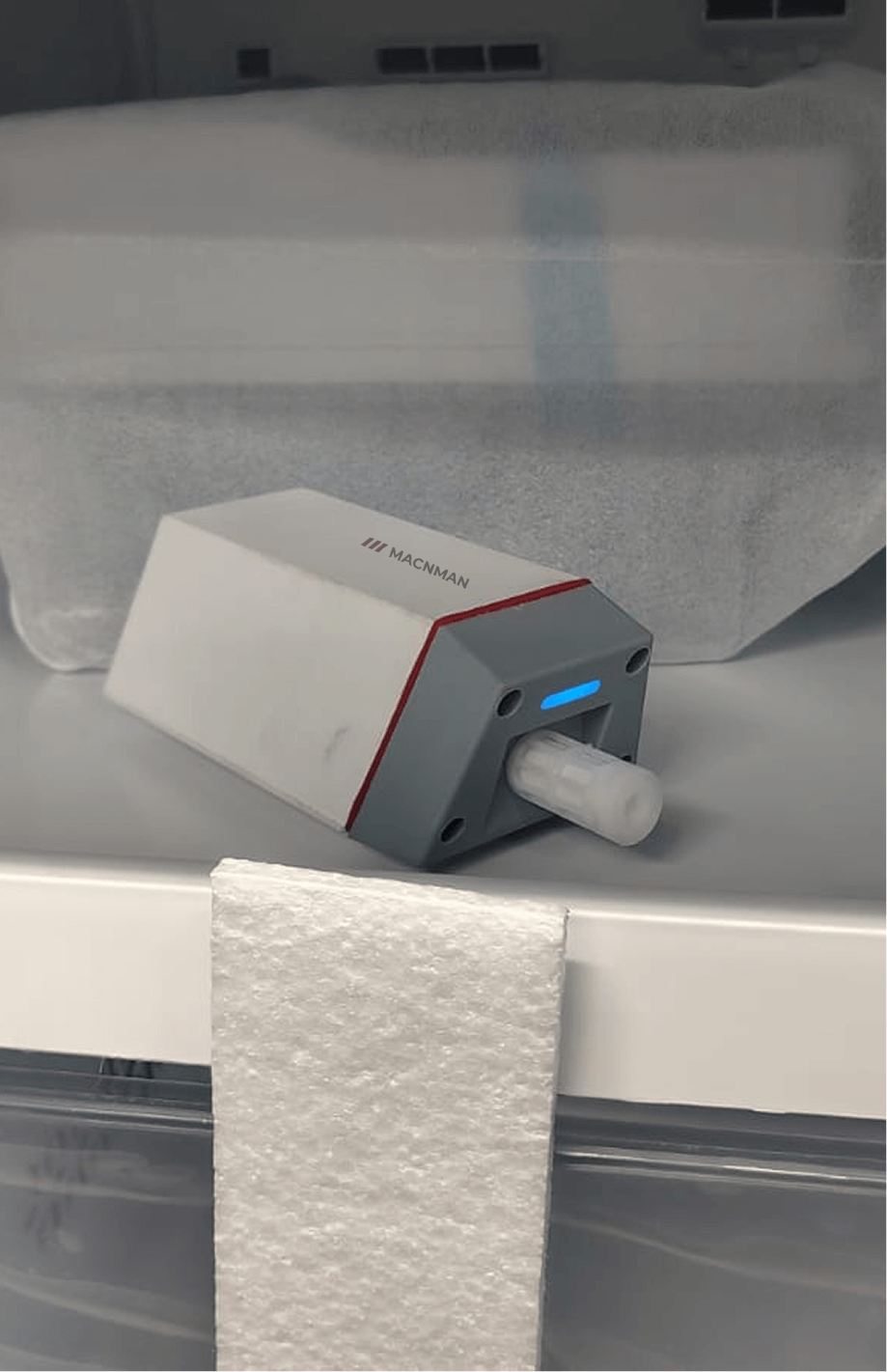

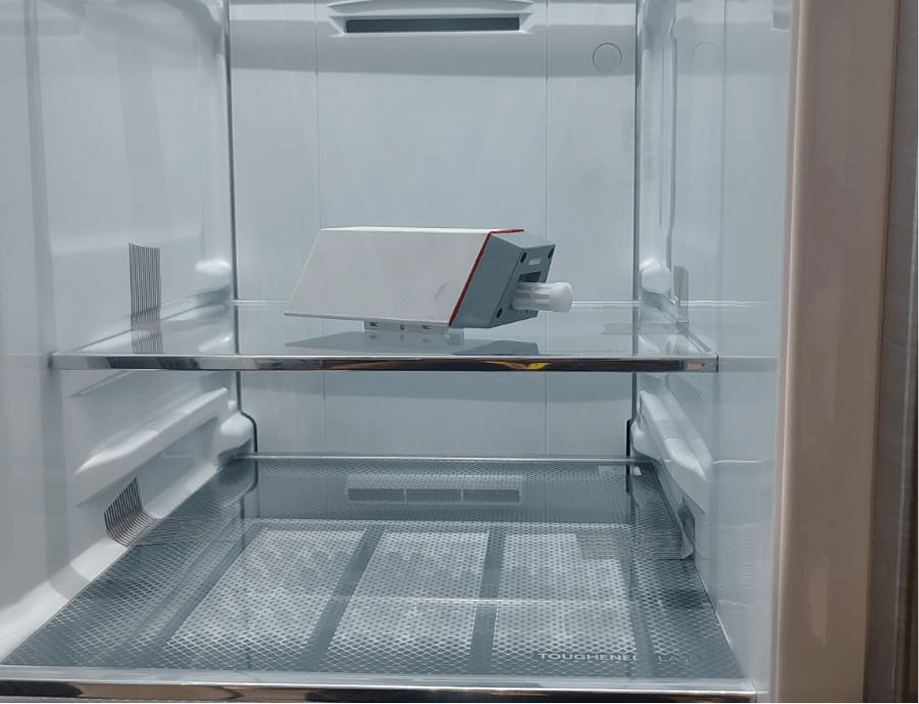

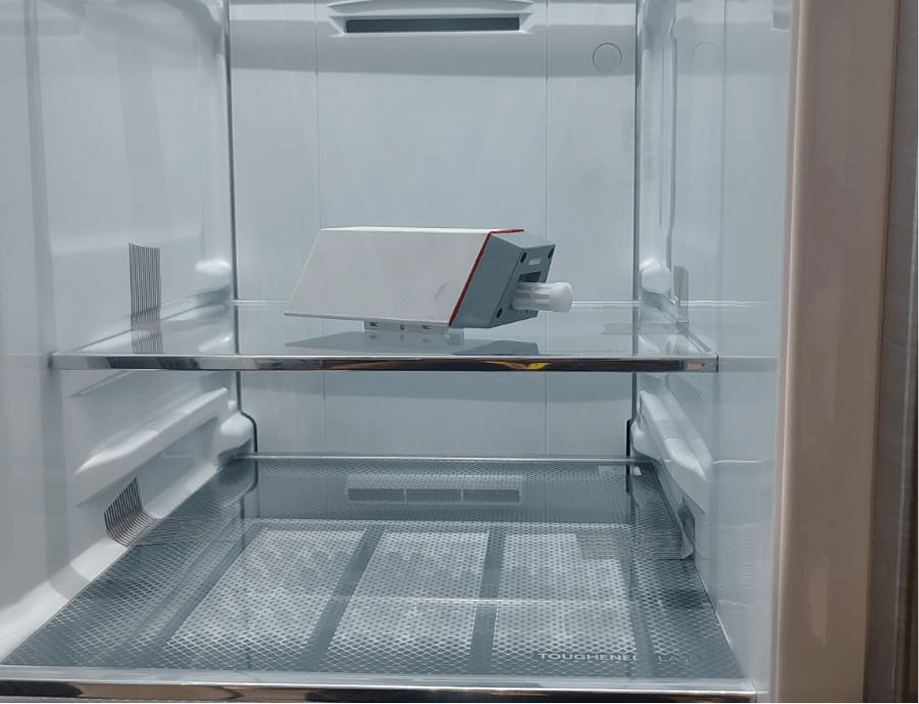

Industrial LoRaWAN Controller

Automates the humidifier motor operation based on humidity data.

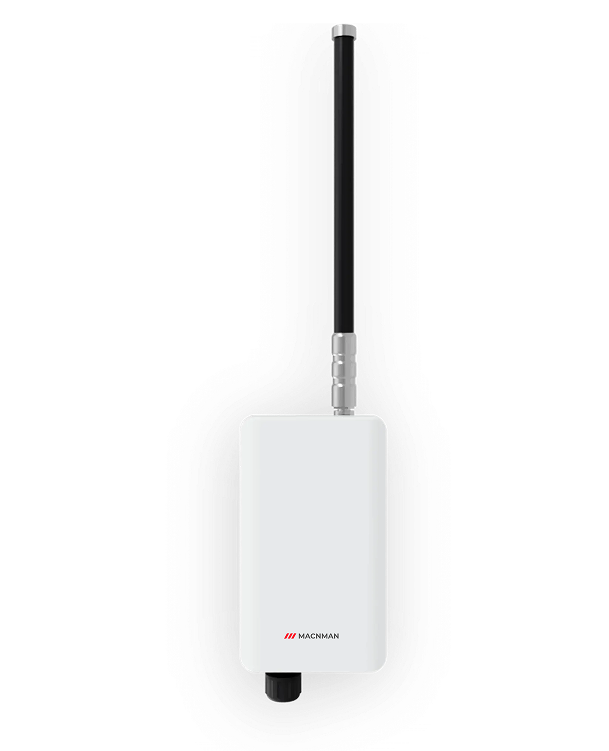

Industrial LoRaWAN Gateways

Positioned at central locations to collect data from all nodes and forward it securely to the cloud platform.

Central Monitoring Dashboard

Provided operators with live status, historical data, and performance analytics for parking utilization and sensor uptime.

The Real Challenges Inside a Floriculture Cold Room (And Where Quality Loss Begins)

Unstable Temperature Control

Frequent fluctuations inside the cold room led to premature wilting and reduced flower shelf life

Inconsistent Humidity Levels

Lack of real-time humidity tracking caused the flowers to dry out or retain excess moisture.

Manual Operation of Humidifiers

Operators had to switch humidifiers on/off manually, often leading to delayed action and improper moisture control.

No Remote Monitoring Capability

The absence of a connected system made it impossible to check real-time conditions without being physically present.

Validation & Reference Testing: Proving the Data Before Trusting the System

Temperature & Humidity Accuracy

Tested LoRaWAN-based sensors to ensure precise monitoring of cold storage conditions for flowers.

Automated Humidifier Activation

Validated system response to thresholds, confirming humidifiers maintain ideal humidity for flower freshness.

Data Integrity and Dashboard

Cross-checked sensor data with local readings to guarantee accurate monitoring and actionable insights for cold storage managers.

Reliable 24/7 Operation Confirmed

Extended testing ensured uninterrupted operation, protecting flowers and optimizing cold storage efficiency.

Why LoRaWAN Matters Here: Stable Monitoring Without Wi-Fi Dependency

Enhanced Flower Shelf Life

Maintaining ideal humidity and temperature levels extended the freshness period, reducing spoilage and waste.

Automated Humidifier Control

The humidifier automatically adjusted based on real-time humidity data, eliminating manual intervention.

Real-Time Monitoring

The farm owner could now monitor cold storage conditions remotely through the Macsync web dashboard.

Energy-Efficient Operations

Optimized on/off control reduced power consumption and improved compressor lifespan.

Conclusion: Protecting Flower Freshness with Stable Temperature, Humidity and Door Control

In floriculture, cold storage performance is not measured by whether the cooling unit is running it’s measured by how consistently the room maintains the right environment for every batch of flowers.

By implementing LoRaWAN-based temperature, humidity, and door status monitoring, the client moved from periodic manual checks to continuous visibility of real cold room conditions. This helped identify hidden fluctuations, reduce unnecessary exposure during door activity, and maintain stable storage conditions throughout daily operations.

The result is a cold storage setup that is easier to manage, easier to control, and far more reliable for protecting flower freshness, reducing shrinkage, and avoiding avoidable financial loss.

This project was not about fixing a failure it was about building a system that keeps performance stable every single day.

Ready to Transform Your Cold Storage with IoT?