Industrial Weather Monitoring with LoRaWAN Sensors (PM2.5 PM 10 CO2)

Maintaining optimal environmental conditions is critical in industrial facilities to ensure equipment longevity, worker safety, and uninterrupted production. At this plant, we deployed Macnman LoRaWAN weather stations to monitor temperature, humidity, and air pressure in real time. The long-range, low-power LoRaWAN network delivers continuous, reliable data to central dashboards, empowering managers with actionable insights, enabling proactive decisions, and reducing operational risks.

Problems Industrial Weather Monitoring Challenges: Avoid Downtime & Safety Risks

Ensuring accurate and real-time environmental data for industrial operations is critical to avoid safety risks and production losses.

Unreliable Weather Data

Manual or outdated monitoring caused unexpected downtime.

Equipment Vulnerability

Lack of real-time alerts put machinery at risk from extreme conditions.

Production Inefficiency

Poor weather insights led to suboptimal operational planning.

Compliance Risks

Failure to monitor conditions affected safety and environmental compliance.

Solution: Real-Time Industrial Weather Monitoring with LoRaWAN

Proposed Solution: A LoRaWAN-based weather station with multi-sensor integration, real-time monitoring, and automated alerts for industrial environments.

- 01

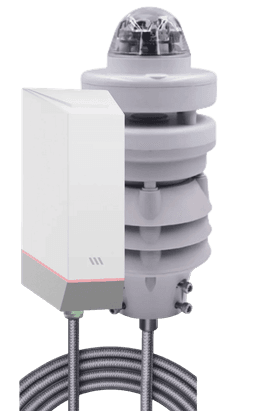

Multi-Sensor Integration

Monitors temperature, humidity, pressure, and wind conditions in real-time.

- 02

LoRaWAN Connectivity

Enables long-range, low-power communication from remote industrial sites.

- 03

Centralized Dashboard

Displays live data and historical trends for operational decision-making.

- 04

Automated Alerts

Sends notifications when environmental thresholds are exceeded.

- 05

Low Maintenance

Sensors are easy to install and running on the solar energy so overall maintenance cost of the system is low

- 06

Reliable Power & Enclosure

IP67-rated, solar-assisted setup ensures continuous operation in harsh conditions.

LoRaWAN Weather Station Architecture

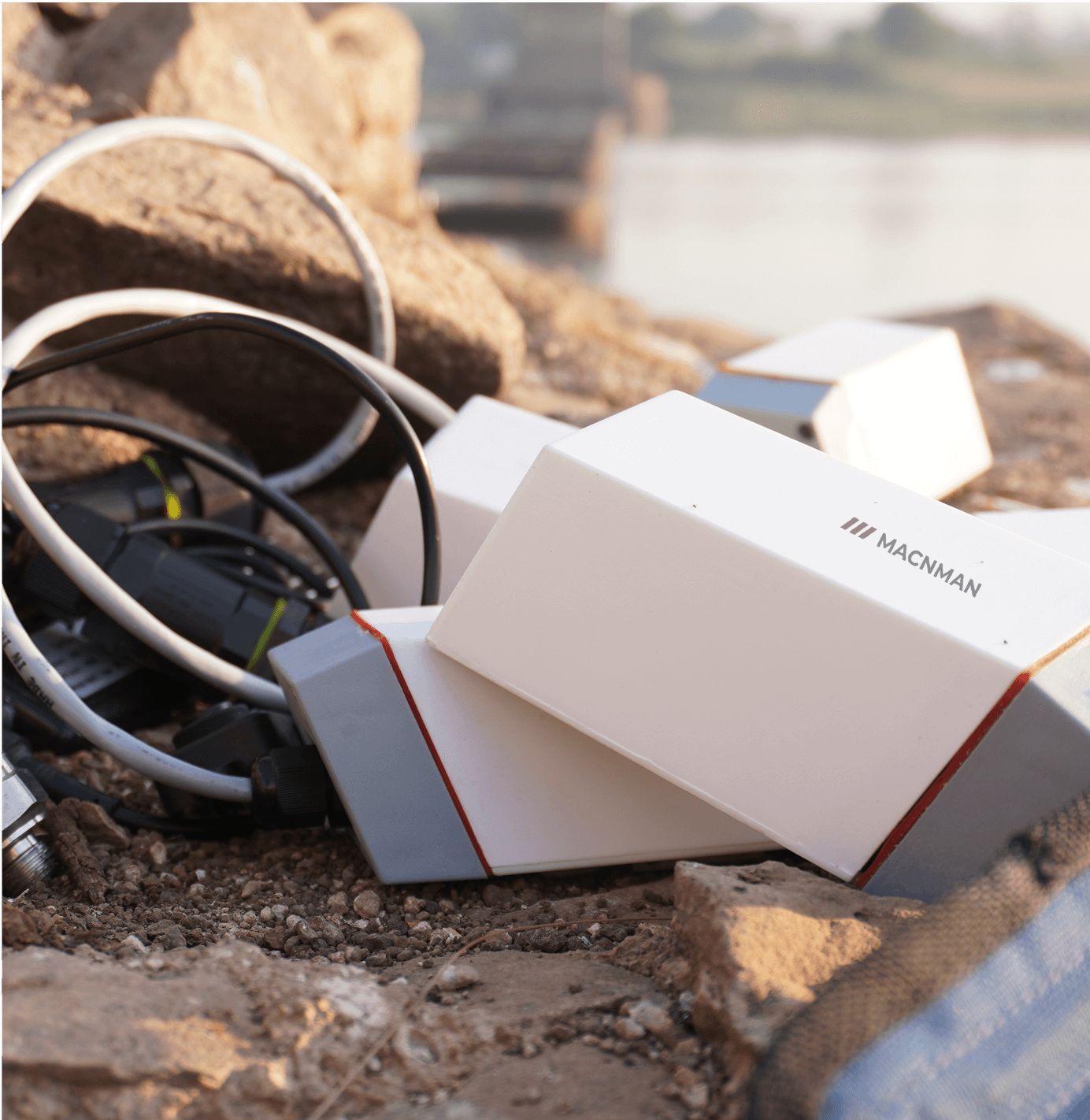

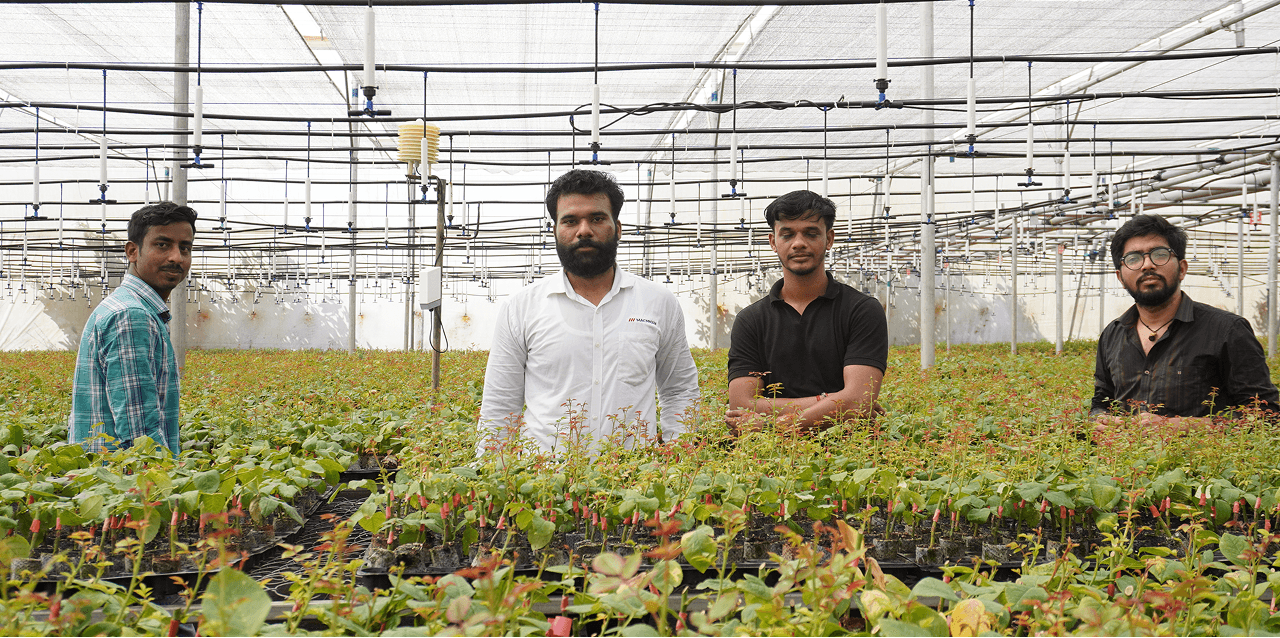

Deployment of Industrial LoRaWAN Weather Station Deployment for Real-Time Monitoring

Deployment of Industrial Weather Sensors: Strategic placement of LoRaWAN weather sensors across the industrial site, connected to gateways and the central dashboard for seamless data collection and monitoring.

MacSync Weather Station

Mounted on a sturdy pole at an open field location to ensure unobstructed wind and sunlight measurements.

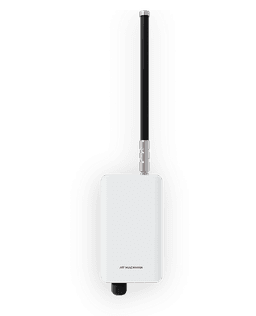

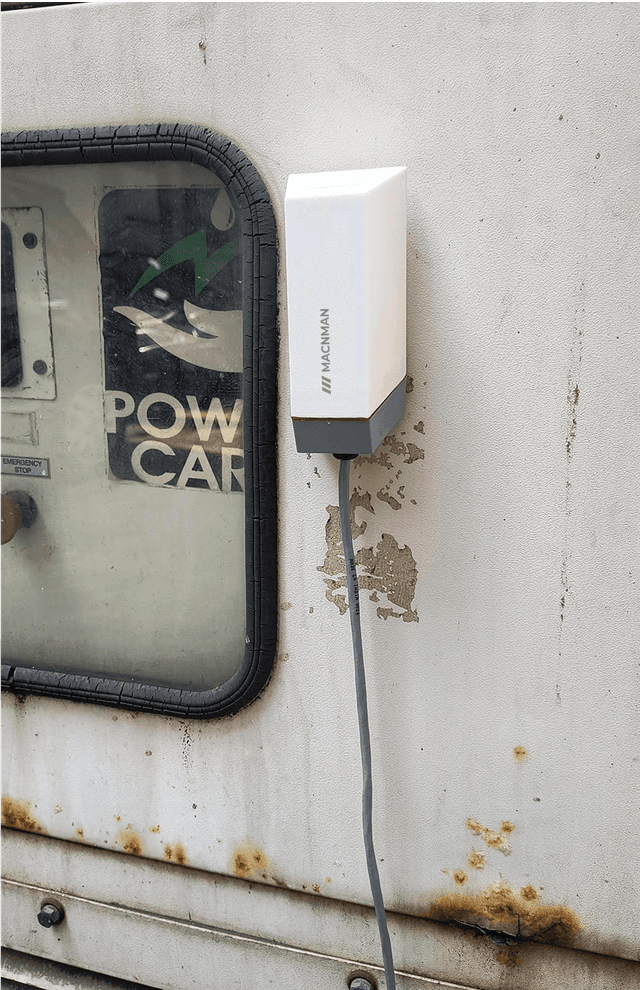

Industrial LoRaWAN Gateways

Positioned at central locations to collect data from all nodes and forward it securely to the cloud platform.

Central Monitoring Dashboard

Provided operators with live status, historical data, and performance analytics for parking utilization and sensor uptime.

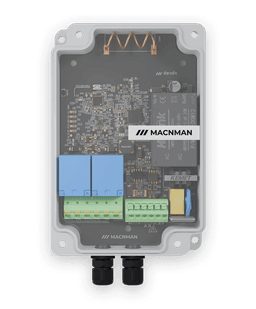

Industrial LoRaWAN Controller

Installed at the central rooms to give any alerts from the servers to teams in case of any parameters are crossing the thresholds.

Overcoming Industrial Weather Monitoring Challenges

Overcoming Urban Signal Barriers

Ensuring stable LoRaWAN connectivity across dense city infrastructure for reliable weather data.

Weatherproofing for Reliable Data

Protecting sensors from rain, dust, and extreme temperatures to maintain uninterrupted monitoring.

Sensor Accuracy & Calibration

Sensors calibration was needed to ensure real-time accuracy for temperature, humidity, and rainfall data.

Weatherproofing Protection

Continuous exposure to dust and moisture required rugged enclosures for long-term reliability.

Validation: How We Ensure Industrial Weather Station Data Accuracy

Data Accuracy and Benchmarking

Before deployment, every sensor was individually calibrated in a controlled lab environment against a certified reference instrument

Co-Location Benchmarking

In the field, one of our LoRaWAN nodes was co-located next to a high-end, traditional wired meteorological station used by the local authority.

Network Reliability and Operational Metrics

The long-term value of an industrial IoT weather station hinges on its consistent, autonomous operation

Reduced Field Maintenance

The static (non-moving part) design of critical sensors, such as wind speed/direction, has been validated to eliminate the need for yearly mechanical calibration

Impact of Industrial Weather Station for Smart Factories & Production Efficiency

95% Reduction in Maintenance Costs

LoRaWAN's low power consumption allows stations to run autonomously for up to 5 years on a single battery, eliminating frequent service trips.

Real-Time Microclimate Hazard Alerts

Instant, location-specific data on wind and precipitation drives immediate action, preventing costly operational downtime and ensuring site safety compliance.

60% Faster Critical Data Latency

Data-driven decisions improve traffic, energy, and public services efficiency.

Seamless SCADA/IoT Integration

Standardized APIs allow for plug-and-play integration with existing SCADA, analytics, and data management platforms in less than 72 hours.

Conclusion: Transforming Industrial Operations with LoRaWAN Weather Monitoring

The implementation of the industrial weather station based on LoRaWAN has fundamentally reshaped our client's approach to environmental risk management and operational efficiency. This solution successfully transcends the limitations of legacy monitoring systems by delivering an unparalleled combination of performance, cost savings, and data quality.

Ready to Transform Your Industry with IoT?