Milk Transport Trucks Monitoring

Maintaining the ideal temperature and humidity during milk transportation is crucial for product quality and compliance. Macnman Technologies, with its LoRaWAN-based environmental sensing solution, helped automate real-time monitoring of milk trucks—ensuring every journey meets the highest safety and quality standards.

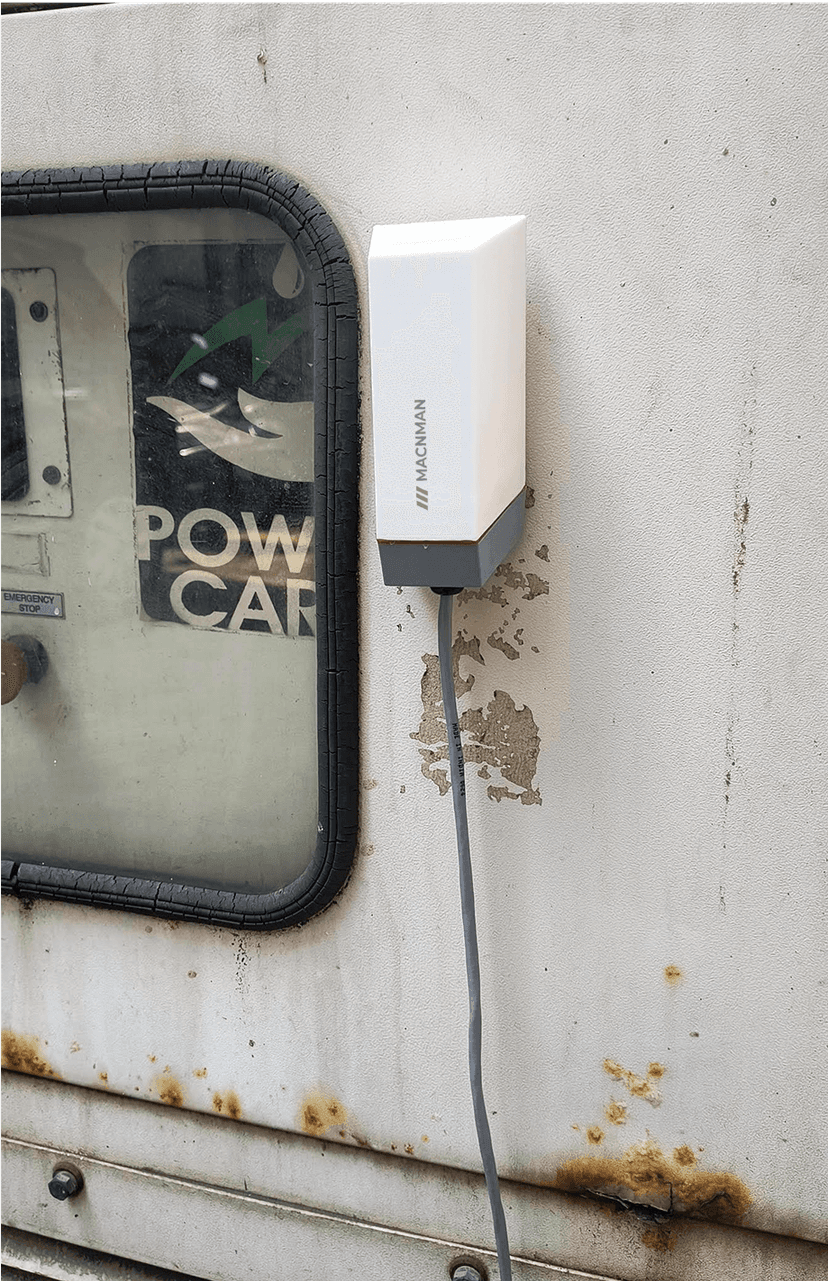

By integrating MacSync LoRaWAN Temperature, Humidity, and Pressure Sensors inside the trucks and deploying LoRaWAN Gateways in the driver’s cabin, the system provided continuous visibility of goods and vehicle location — even in remote regions with poor network connectivity.

This deployment empowered the logistics team to detect anomalies, prevent spoilage, and maintain data logs for compliance audits — redefining the way perishable goods are monitored on the move.

Problem: Cold Chain Monitoring Challenges in Milk Transportation

Ensuring milk quality during transit is critical for food safety, compliance, and customer trust. Transporting perishable dairy products faced several hurdles:

Unstable Temperature & Humidity

Milk trucks lacked real-time monitoring, leading to spoilage risks.

No Real-Time Tracking

Fleet operators couldn’t monitor environmental conditions or truck location remotely.

Manual Data Logging

Paper-based checks caused errors, incomplete records, and audit failures.

Delayed Issue Detection

Temperature deviations were only noticed post-delivery, resulting in product loss.

Proposed Solution: Smart LoRaWAN Monitoring for Milk Transport

Macnman deployed a LoRaWAN-based temperature, humidity, and pressure monitoring system across the milk transport fleet, enabling real-time visibility and proactive control:

- 01

Vehicle Cabin Sensors

Monitored temperature, humidity, and pressure to ensure optimal milk conditions.

- 02

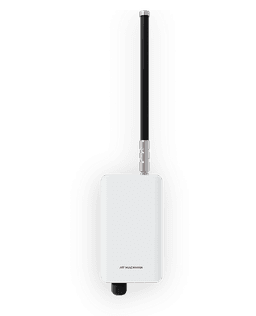

Onboard LoRaWAN Gateway

Collected sensor data and transmitted it securely to the cloud in real-time.

- 03

Remote Dashboard Access

Fleet owners could track vehicle location and environmental conditions anytime, anywhere.

- 04

Automated Alerts

Instant notifications if conditions deviated from set thresholds, preventing spoilage.

- 05

Data Logging & Compliance

Continuous recording of environmental parameters for audits and regulatory compliance.

- 06

Seamless Integration

System worked with existing fleet operations without modifying vehicle infrastructure.

LoRaWAN Architecture for : Real-Time Milk Transport Monitoring

Deployment: Smart Ultrasonic Parking System & Existing Infrastructure

To ensure safe and traceable delivery of milk products, Macnman deployed the following devices in each truck:

Temperature & Humidity Sensors

Installed in the cargo compartment to monitor real-time conditions of the milk during transit.

Industrial LoRaWAN Gateways

Positioned at central locations to collect data from all nodes and forward it securely to the cloud platform.

Central Monitoring Dashboard

Provided operators with live status, historical data, and performance analytics for parking utilization and sensor uptime.

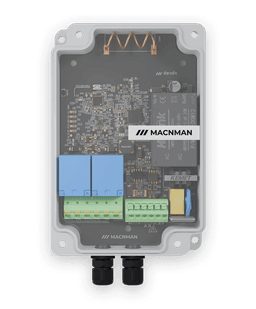

Industrial LoRaWAN Controller

Installed at all truck driver cabin to display real-time values and alerts through indicator lights.

Deployment Challenges: Ensuring Reliable Underground Water Level Monitoring

Connectivity Across Routes

Trucks traveled through remote areas with weak network signals, requiring long-range LoRaWAN solutions

Sensor Accuracy

Maintaining precise temperature, humidity, and pressure readings during bumpy or long hauls was critical.

Power Management

Sensors and gateways needed to run continuously without frequent maintenance or battery replacements.

Environmental Extremes

Vehicles faced heat, vibration, and humidity fluctuations, demanding rugged, farm-ready IoT devices.

Validation: Ensuring Cold Chain Reliability for Milk Transport

Precise Temperature Monitoring

Calibrated sensors ensured accurate, real-time temperature tracking inside milk compartments.

Humidity & Pressure Accuracy

Verified sensor readings to maintain optimal humidity and pressure for dairy safety.

Real-Time Alert Validation

Early warning triggers validated for deviations in conditions or unexpected vehicle stops.

Fleet-Wide Performance Checks

Multiple trucks tested to guarantee consistent cold chain monitoring across the fleet.

Impact: From Hidden Data to Real-Time Water Insights

Optimized Cold Chain

Ensured milk stayed within safe temperature and humidity ranges, reducing spoilage.

Data-Driven Decisions

Historical data helps optimize routes, schedules, and vehicle usage for efficiency.

Reduced Operational Risks

Early alerts on temperature or pressure deviations prevent costly product losses.

Enhanced Compliance

Automated logging supports food safety standards and regulatory audits.

Conclusion: Reliable Cold Chain Monitoring with LoRaWAN

With Macnman’s LoRaWAN sensors and gateways, milk transport is now fully monitored in real time, ensuring optimal temperature, humidity, and pressure throughout the journey.

Fleet owners gain actionable insights, early alerts for deviations, and enhanced control over the cold chain. This implementation reduces spoilage, improves product quality, and strengthens supply chain efficiency—all while leveraging low-power, long-range IoT technology for maximum reliability.

Explore How Macnman Secures Cold Chains