Real-Time Forklift tracking using UWB

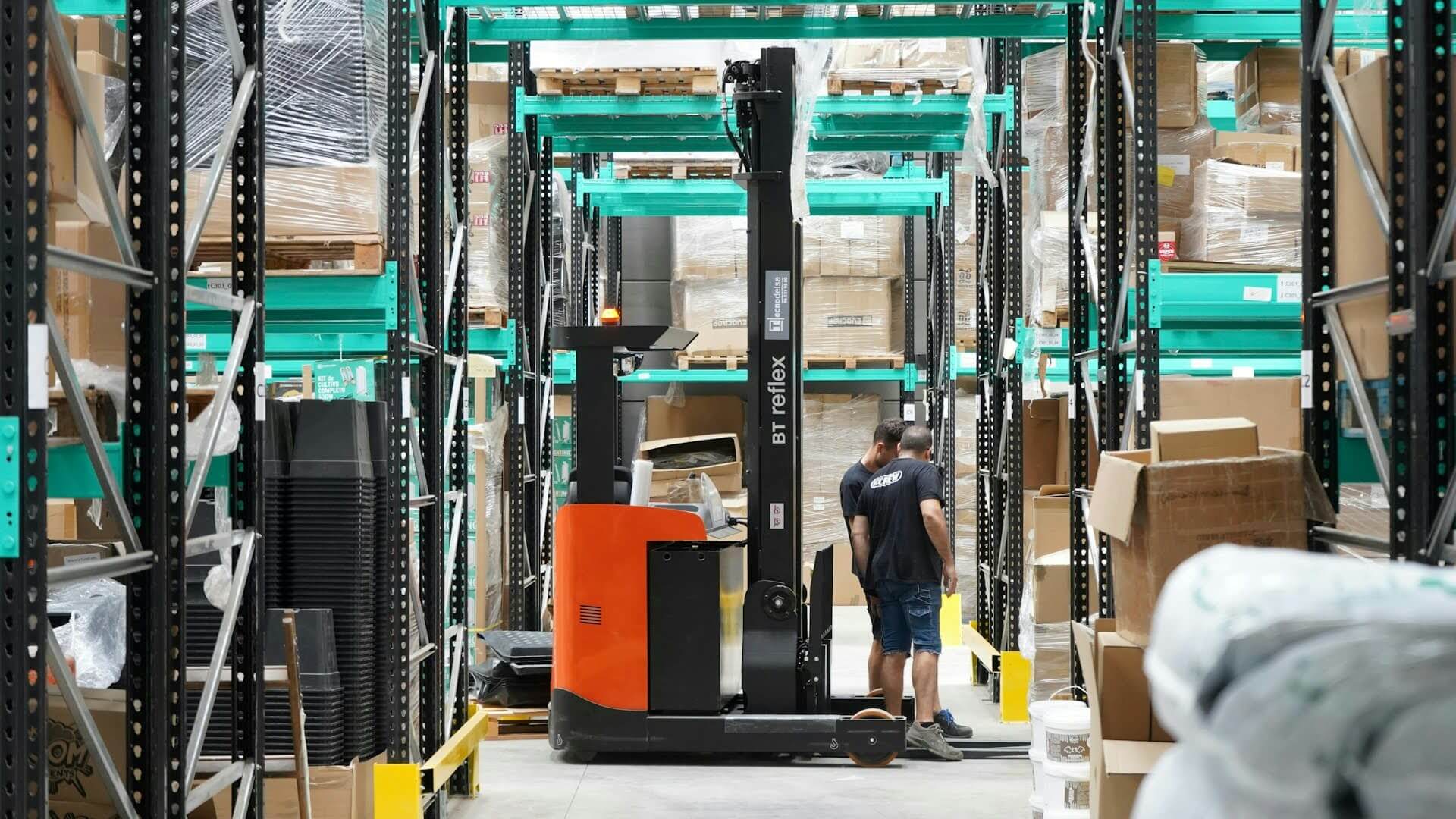

A leading manufacturing facility struggled daily with poor visibility of their high-value assets. Forklifts, material trolleys, and pallets routinely went “missing” inside the huge plant, causing production delays. Manual calling, physical search, and guesswork became the default way to track asset movement.

Without a real-time indoor tracking system, the team had no clue where assets moved, how long they stayed idle, or whether they were used efficiently.

Small delays turned into major productivity losses, pushing the management to look for a high-accuracy indoor positioning system that worked inside metal-heavy spaces and delivered real-time location accuracy within 10–20 cm.

They needed a UWB RTLS solution that could provide continuous visibility, asset movement analytics, and zero-blind-spot tracking across the entire shop floor.

The Problem: Zero Visibility. High Wastage. Slow Operations.

Before adopting the Macnman UWB RTLS, the facility faced critical operational blind spots that directly increased costs and slowed production.

Lack of Real-Time Forklift Tracking

Forklift movements were manually logged, leading to delays and inaccurate data.

Route Congestion and Idle Time

Forklifts often followed inefficient paths, creating congestion and operational delays.

Inefficient Asset Movement

Inventory and material handling lacked visibility, causing workflow disruptions.

Unmonitored Fuel Consumption

Without live data, fuel wastage and misuse were difficult to detect and control.

The Solution: A High-Accuracy UWB RTLS That Eliminated Every Blind Spot

To fix the visibility gaps and operational delays, the facility deployed the Macnman UWB Real-Time Location System (RTLS) — a precision indoor tracking solution engineered for sub-20 cm accuracy and seamless coverage across high-density industrial environments.

- 01

Forklift Tracking with UWB Tags

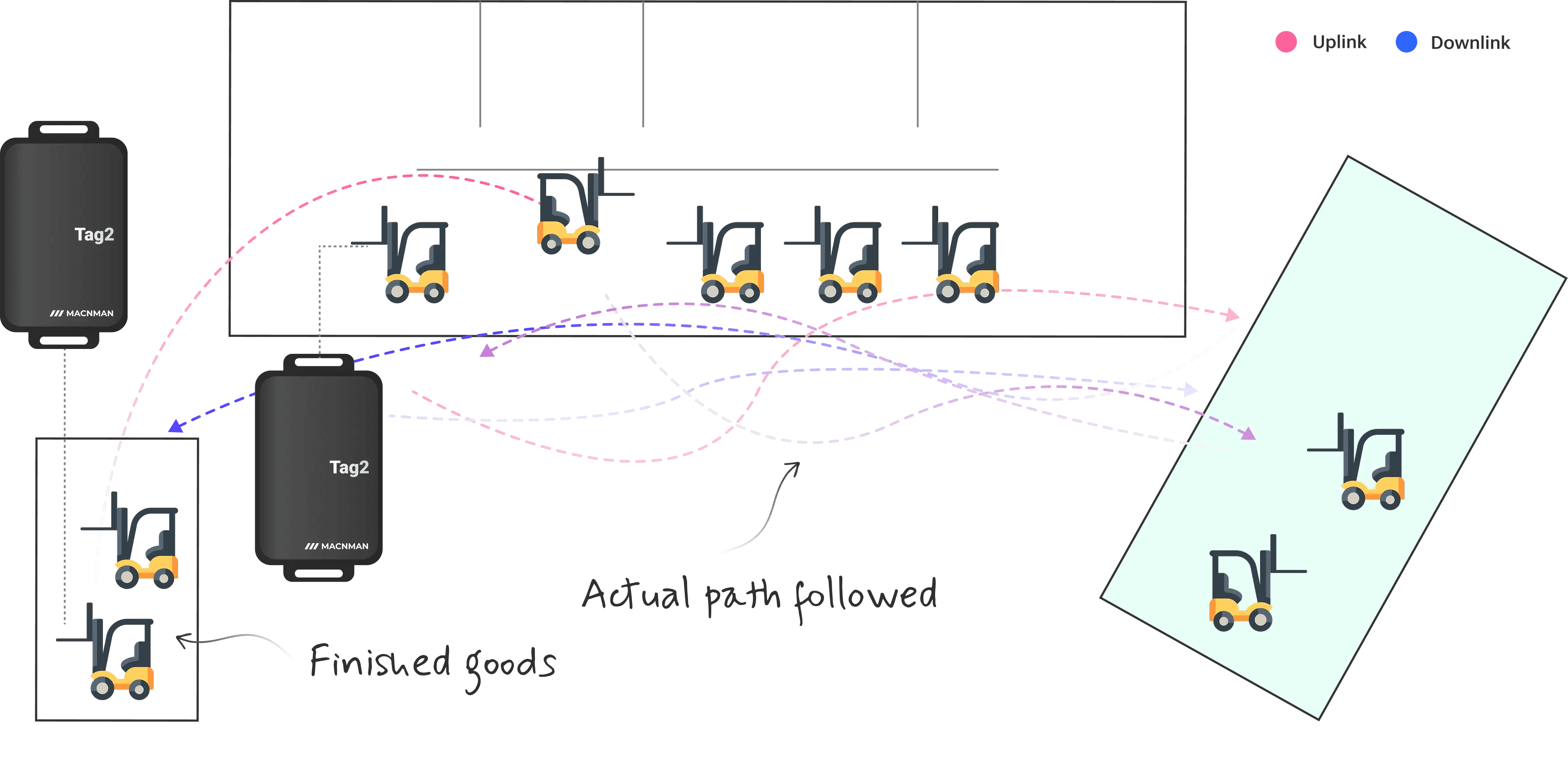

Each forklift was equipped with a UWB Tag that continuously transmitted real-time location data to the network.

- 02

LoRaWAN Connectivity

The tags and gateways used LoRaWAN for seamless data transmission even in large industrial environments

- 03

Fuel Monitoring Integration

Fuel sensors were added to track live fuel levels, consumption rates, and refueling activities.

- 04

Asset and Inventory Tagging

High-value assets and inventory trolleys were tagged to provide real-time visibility of their location and movement

- 05

Preventive Alerts

Instant notifications for deviations from set thresholds, reducing flower spoilage risk

- 06

Centralized Monitoring Dashboard

A unified dashboard displayed forklift positions, usage time, and performance analytics, helping supervisors make data-driven decisions instantly.

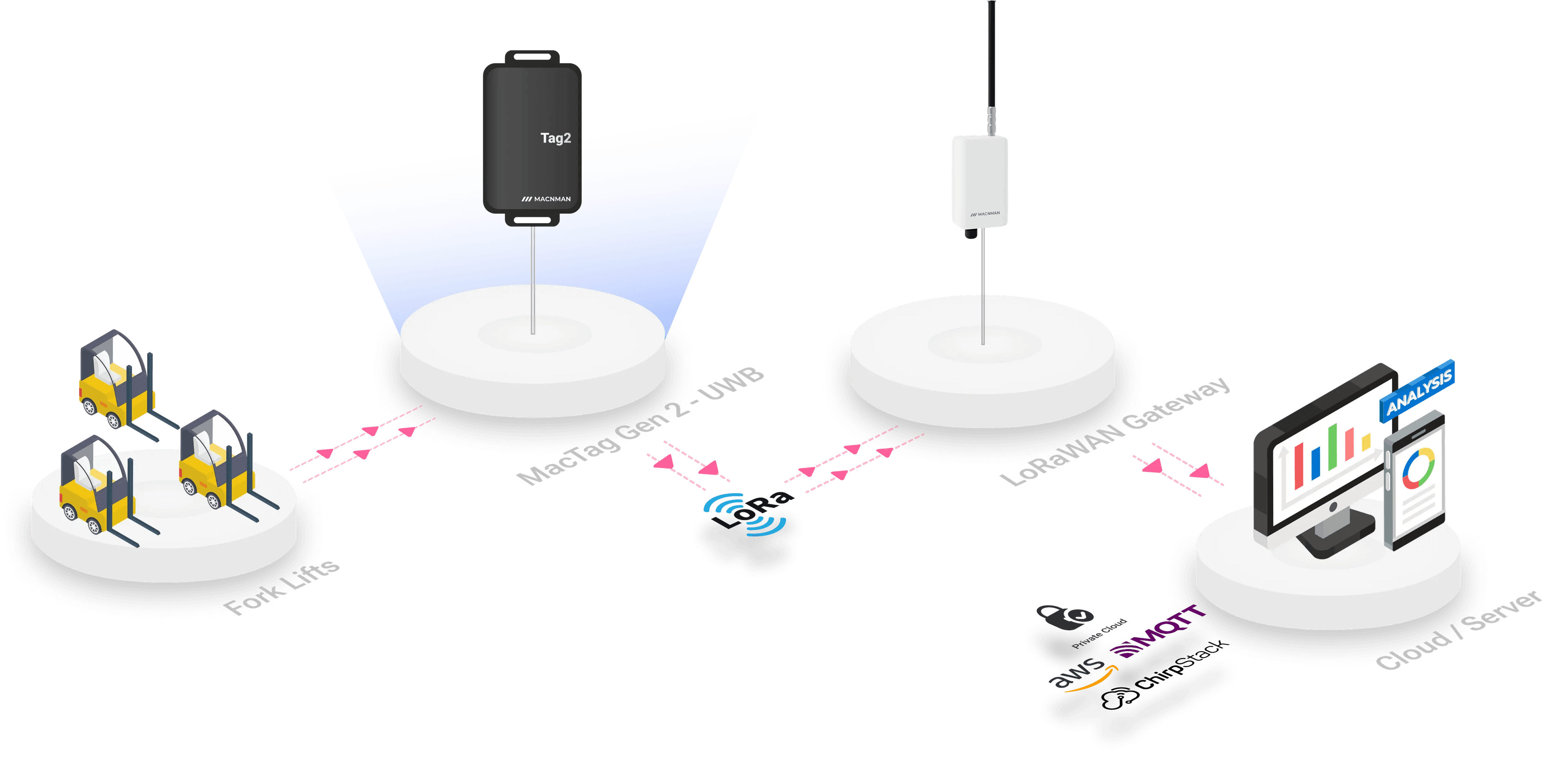

System Architecture: A High-Precision UWB RTLS Built for Industrial-Grade Accuracy

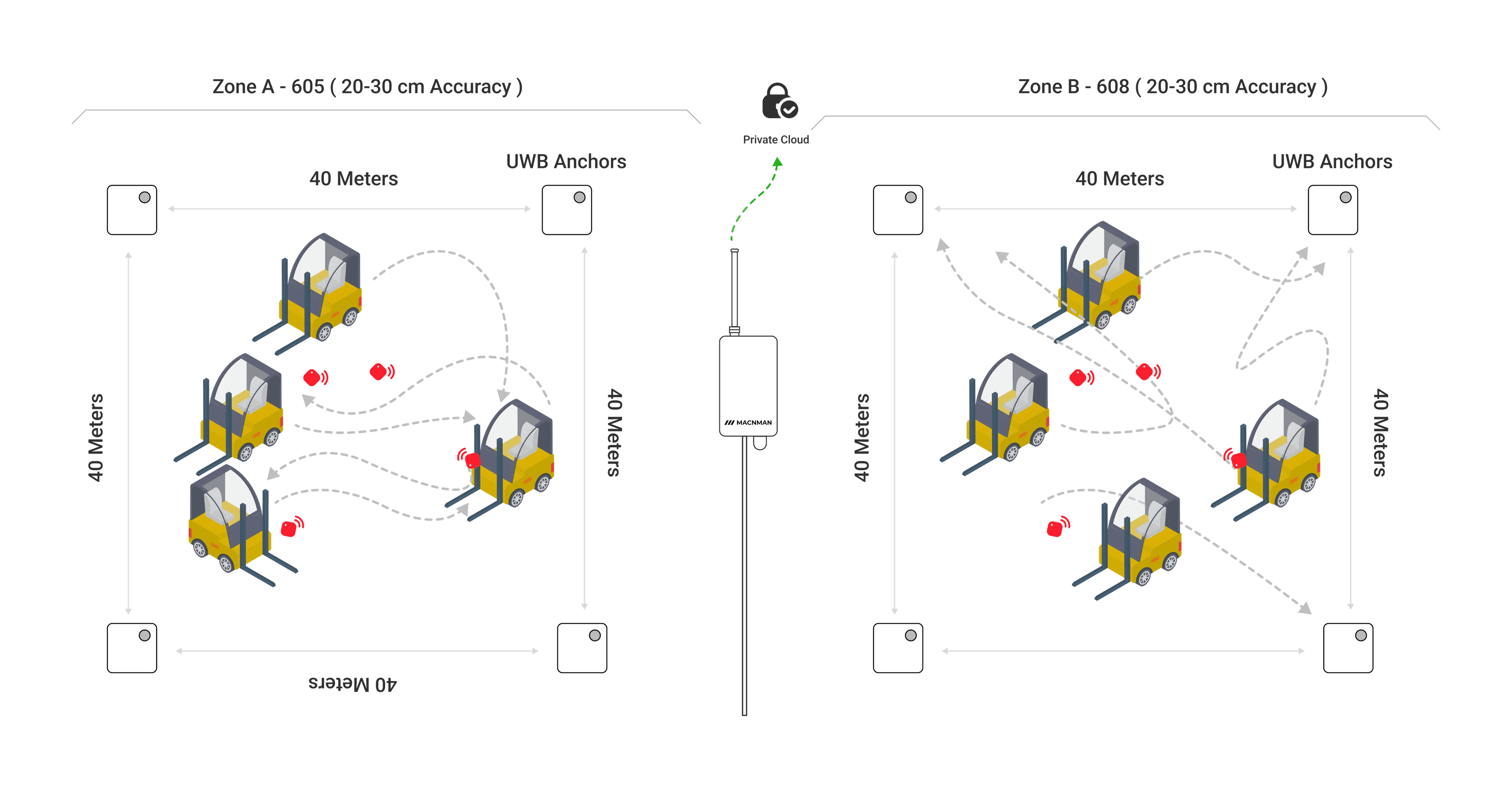

Deployment: Precision Placement of Anchors, Tags for Full Forklift Visibility

The deployment was engineered around actual forklift movement patterns, not a generic floor layout. Every device was installed only where it delivered maximum operational impact.

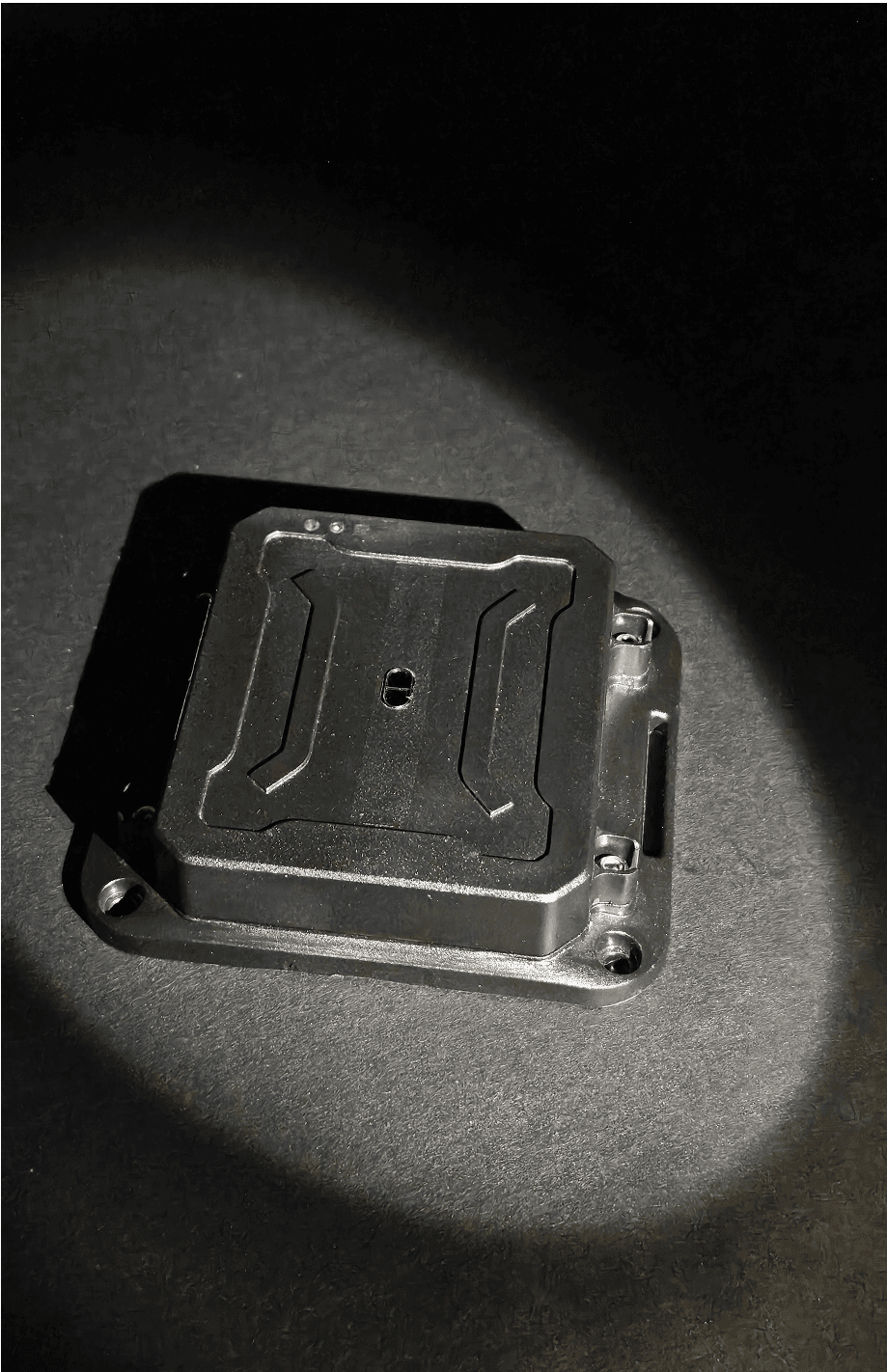

UWB Tags

Provided continuous, real-time tracking of location and movement inside the plant.

UWB Anchors

A total of 28 MacSync UWB Anchors were mounted on Primary forklift lanes Corners and turning points Loading/unloading bays.

Industrial LoRaWAN Gateways

Connected anchors and sensors to the central server over long-range, low-power wireless communication.

Central Monitoring Dashboard

Enabled supervisors to track forklifts, inventory location, fuel consumption, and usage patterns in real-time.

UWB RTLS deployment with anchor placement and forklift-mounted tags for real-time tracking

Heavy Metal Machinery Causing Signal Reflections

Metal racks and machines created multipath zones where forklifts frequently lost visibility.

Congested Forklift Intersections

High-traffic junctions caused overlapping movements, making accurate position tracking difficult.

Rapid Forklift Acceleration & Sharp Turns

Fast movement required a system capable of processing high-frequency location bursts without lag.

Blind Spots Near Loading & Staging Zones

Critical loading areas had inconsistent visibility due to height differences and equipment density.

Validation: Cold Storage IoT System Validation and Testing

Accuracy Validation

Achieved consistent sub-20 cm precision across forklift lanes, intersections, and metal-heavy areas.

Coverage Validation

Validated system response to thresholds, confirming humidifiers maintain ideal humidity for flower freshness.

Idle-Time Detection Validation

System correctly differentiated productive stops from wasteful idle time with high accuracy.

Load & Stress Validation

Handled simultaneous tracking of multiple forklifts with zero packet loss and no dashboard latency

Impact: Fast Operational Wins With Immediate Measurable ROI

Full Forklift Transparency Across Every Shift

Live tracking removed all blind spots, enabling supervisors to monitor every movement in real time.

38% Drop in Fuel Lost to Idle Time

The system flagged wasteful stops, cutting unnecessary fuel burn within the first month.

Faster Material Movement With Smoother Routes

Optimized routing reduced congestion, shortened travel loops, and improved cycle efficiency.

Zero Lost or Delayed Material Trolleys

Continuous visibility ensured every forklift reached the right zone without delays.

Conclusion: LoRaWAN Cold Storage Results and Future

The deployment of the Macnman UWB RTLS transformed the client’s forklift operations from guesswork to real-time, data-driven control. Every forklift’s movement, route, idle stop, and fuel-impacting behavior became fully visible—eliminating blind spots, cutting fuel wastage, and streamlining material flow across the facility.

With accurate tracking, optimized routing, and instant alerts for inefficiencies, the client now operates with higher speed, lower fuel costs, and total operational transparency. The solution not only fixed long-standing productivity issues but also created a scalable foundation for smarter, safer, and more efficient forklift-driven operations.

Ready to Transform Your Cold Storage with IoT?